In the current era of vigorous development in the ready-to-eat food industry, pre-prepared food plants are confronted with the severe challenge

of ensuring the freshness and hygiene safety of ingredients. As an innovative device, hypochlorous acid generators are gradually emerging,

providing an efficient, safe and environmentally friendly solution for the preservation and disinfection of ready-to-eat meals

1,The sterilization and preservation principle of hypochlorous acid

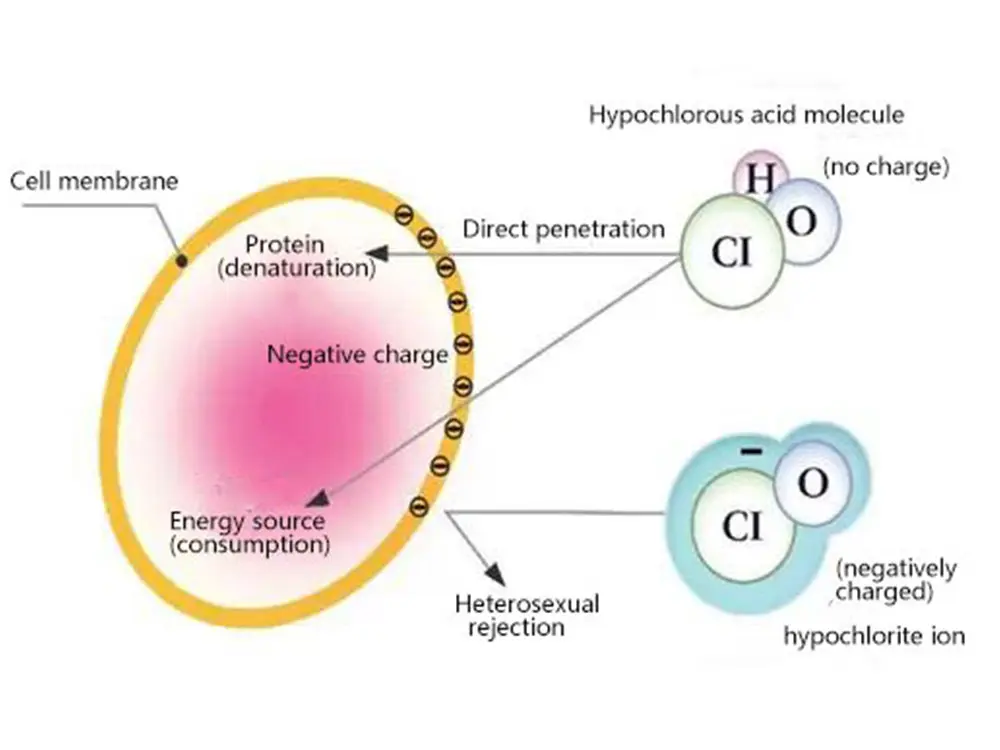

1,1)Hypochlorous acid (HClO) is a strong oxidant, and its bactericidal mechanism is unique and highly efficient. On the one hand,

hypochlorous acid molecules are small and electrically neutral, and can easily penetrate the cell walls and cell membranes of bacteria,

viruses and other microorganisms. Once inside the cell, hypochlorous acid will undergo oxidation reactions with key biomolecules

such as enzymes, proteins and nucleic acids within the cell, disrupting the normal physiological functions of the cell and

leading to the death of microorganisms. For instance, hypochlorous acid can oxidize the respiratory enzymes within bacterial cells,

rendering them inactive and thereby blocking the energy supply to the bacteria, thus achieving the purpose of sterilization.

1,2)On the other hand, hypochlorous acid can decompose the polysaccharide substances on the surface of bacteria,

further weakening the structural integrity of bacteria and accelerating their death process. This dual mechanism of action enables hypochlorous acid to

exhibit powerful bactericidal effects at low concentrations and is effective against a variety of bacteria, fungi and viruses. According to research,

hypochlorous acid can efficiently kill common foodborne pathogenic bacteria such as Escherichia coli, Staphylococcus aureus,

and Salmonella within a short period of time, with a sterilization rate of over 99.99%.

1,3)In terms of preservation, hypochlorous acid mainly functions by inhibiting the production of ethylene. Ethylene is a gas that promotes the ripening and aging of food.

Many fruits and vegetables continuously release ethylene after being picked, accelerating their own ripening and rotting processes.

Hypochlorous acid can effectively control the release of ethylene from food, delay its maturation process,

and thereby extend the freshness and shelf life of food. Meanwhile, hypochlorous acid can also regulate the respiratory metabolism of food after harvest,

reduce its respiratory intensity, decrease the consumption of nutrients, and further maintain the quality of food.

2,Application scenarios of hypochlorous acid generators in ready-to-eat meals

2,1 The cleaning and disinfection of food ingredients by hypochlorous acid

In the prefabrication plant, a large number of vegetables, fruits, meats and aquatic products and

other ingredients need to be washed and disinfected. Soaking or spraying the ingredients with hypochlorous acid solution produced by

the hypochlorous acid generator can effectively remove dirt, pesticide residues and microorganisms on the surface of the ingredients.

Compared with traditional cleaning and disinfectant agents, hypochlorous acid has the characteristics of no residue, no toxicity and low odor,

and will not have adverse effects on the quality and taste of food ingredients. For instance, for vegetables and fruits,

hypochlorous acid solution can kill harmful microorganisms on the surface while maintaining their bright color, crisp and tender texture, and extending their shelf life

2,2 Disinfection of processing equipment and the environment with hypochlorous acid

The processing equipment, workbenches, floors and air in the prefabrication yard all need to be disinfected regularly to

prevent the growth of microorganisms and cross-contamination. The hypochlorous acid solution produced by the hypochlorous acid generator

can be use for CIP (in-situ cleaning) sterilization inside the equipment and COP (off-site cleaning) sterilization on the surface of objects.

By spraying or wiping, it can quickly and effectively kill bacteria, viruses, fungi and other microorganisms on the surface of the equipment and in the environment. In addition,

hypochlorous acid can also be used for air disinfection. By atomizing hypochlorous acid through atomization equipment and releasing it into the air,

it can effectively kill pathogenic microorganisms in the air and improve the air quality of the processing environment

2,3The preservation of ready-to-eat meals by hypochlorous acid

During the packaging process of ready-to-eat meals, adding an appropriate amount of hypochlorous acid to the packaging materials or

directly spraying it on the surface of the finished ready-to-eat meals can, to a certain extent,

inhibit the growth and reproduction of microorganisms and extend the shelf life of ready-to-eat meals.

Meanwhile, hypochlorous acid has a relatively small impact on the nutritional components of ready-to-eat meals

and can maintain their original flavor and quality. For instance, for some ready-to-eat meals, after being treat with hypochlorous acid for preservation,

their shelf life at room temperature can be extended by several days, and under refrigeration conditions, the shelf life can be significantly prolonged

FAQ

1,Can hypochlorous acid kill bacteria and microorganisms in ready-to-eat meals?

Hypochlorous acid has broad-spectrum bactericidal properties and can quickly and effectively kill a variety of pathogenic microorganisms,

including bacteria, fungi, viruses, etc. Its bactericidal effect is far superior to that of traditional chlorine-based disinfectants,

such as sodium hypochlorite. Research data shows that under the same sterilization conditions, hypochlorous acid kills certain bacteria dozens of times faster than sodium hypochlorite.

2,Is hypochlorous acid safe to use in ready-to-eat meals?

Hypochlorous acid, after sterilization, is restore to water and does not leave any harmful substances on the surface of food ingredients,

equipment or in the environment, thus avoiding the food safety risks and environmental pollution problems caused by the residues of traditional disinfectants.

Even if hypochlorous acid solution is accidentally ingest, due to its low toxicity, it will not cause particularly serious effects on the human body

and poses no threat to the health and safety of operators and consumers

3,Does hypochlorous acid have an impact on the quality of food ingredients?

The low bleaching power and slightly acidic nature of hypochlorous acid have a minimal impact on the nutritional components,

color and taste of food ingredients. In the practical application of the prefabrication plant,

the ingredients treated with hypochlorous acid can better maintain their original freshness and quality, reducing the loss of ingredients caused by the preservation and disinfection process