In the livestock breeding industry, the odor problem in breeding farms has long been a major challenge for practitioners. The foul odors emitted by livestock and poultry manure, sewage, and feed residues not only seriously affect the breeding environment, reduce the quality of life and production performance of livestock and poultry, but also cause disturbances to the lives of surrounding residents, leading to environmental complaints. Therefore, efficient and environmentally friendly deodorization methods have become a problem that must be solved in the livestock industry. Hypochlorous acid generators, as a new type of environmental protection equipment, provide an innovative solution for deodorization in livestock breeding and demonstrate many significant advantages in practical applications

1,The deodorization principle of hypochlorous acid generators

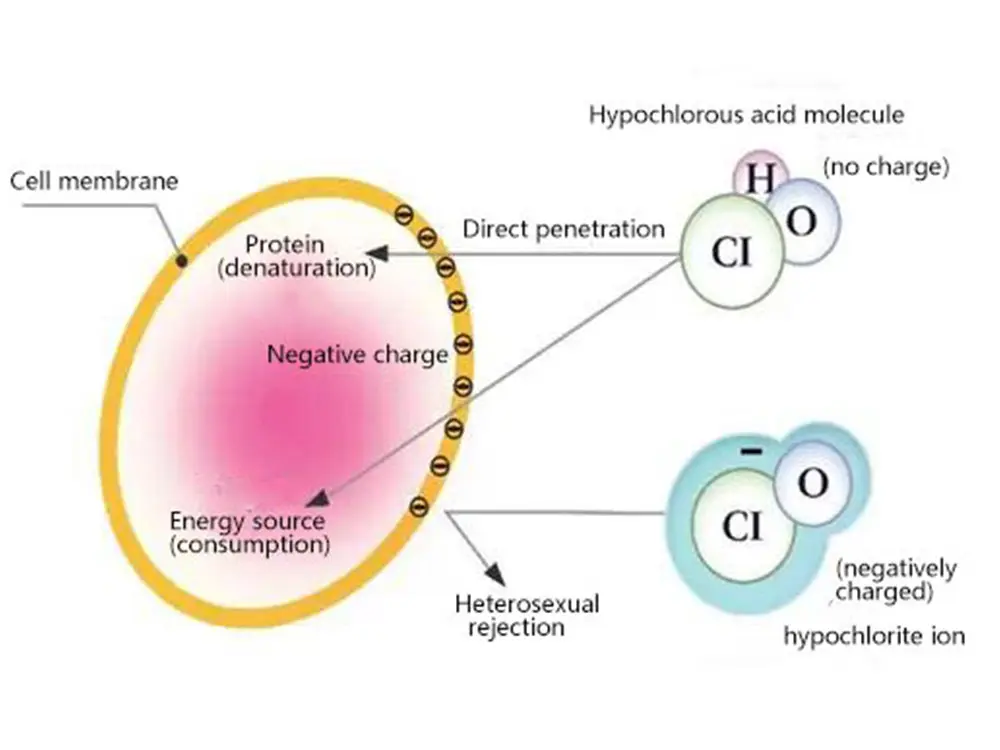

1.1 Hypochlorous acid (HOCL) is a weak acid with strong oxidizing properties. The hypochlorous acid generator generates a high-concentration and highly stable hypochlorous acid solution by electrolyzing dilute hydrochloric acid or sodium chloride and using electrochemical technology in a specific electrolytic cell. Its PH is usually adjusted between 5.0 and 6.5, and the effective chlorine concentration is generally 10-120PPM (adjustable).

1.2 In the livestock breeding environment, odors are mainly divided into ammonia (NH3), hydrogen sulfide (H2S), methyl mercaptan,

trimethylamine, etc. Hypochlorous acid can undergo chemical reactions with these odor molecules. Take ammonia as an example.

Hypochlorous acid reacts with ammonia to form chloramine and water (NH₃ + HClO → NH₂Cl + H₂O),

thereby converting the harmful ammonia into relatively harmless substances and achieving the effect of removing odors.

For malodorous gases like hydrogen sulfide, the strong oxidizing property of hypochlorous acid can oxidize and decompose them,

converting them into stable and odorless substances such as sulfates. Meanwhile, hypochlorous acid can also oxidize and

decompose organic matter in livestock and poultry manure and sewage, reducing the generation of odors from the root. In addition,

hypochlorous acid can rapidly volatilize in the air, releasing hypochlorous acid molecules. These molecules can react with bacteria,

viruses and odor molecules in the air, further purifying the air and improving the air quality of the breeding environment.

2,The application advantages of hypochlorous acid generators in deodorization in livestock breeding

2.1 The highly efficient deodorization capacity of hypochlorous acid

The hypochlorous acid produced by the hypochlorous acid generator has a rapid and obvious removal effect

on various odor components in the livestock breeding environment. Studies show that when the concentration of

hypochlorous acid reaches a certain level (such as greater than 50PPM), it has a relatively good deodorization ability

for common malodorous substances such as cresol, indole, dimethyl trisulfide, and dimethyl disulfide. In practical applications,

simply spraying an appropriate concentration (such as 50PPM) of hypochlorous acid at the rear end of the fan outlet can effectively decompose the odor molecules in the air,

rapidly reduce the odor concentration in the breeding environment, and significantly improve the air quality in the breeding farm.

Compared with traditional deodorization methods, such as physical adsorption deodorization (using adsorption materials like activated carbon),

hypochlorous acid generators can not only adsorb odors but also completely decompose odor molecules through chemical reactions, resulting in more lasting and efficient deodorization effects.

2.2 The highly efficient sterilization and disinfection ability of hypochlorous acid

Hypochlorous acid has a powerful ability to kill bacteria and disinfect. It can quickly eliminate various pathogens in the breeding environment,

including Escherichia coli, Salmonella, Staphylococcus aureus, avian influenza virus, etc. During the process of livestock breeding,

the growth and spread of bacteria and viruses often coexist with poor breeding environments and unpleasant odors. While deodorizing,

the hypochlorous acid generator comprehensively disinfects the air, floor, walls, equipment and the surface of livestock and poultry in the breeding house,

reducing the number of pathogens and lowering the risk of livestock and poultry contracting diseases.

This not only helps ensure the healthy growth of livestock and poultry and improve the efficiency of breeding,

but also reduces the use of drugs caused by diseases, which is in line with the current development concept of green and healthy breeding.

For instance, in some pig farms, after using hypochlorous acid generators for daily disinfection and deodorization work,

the incidence rate of the pig herd has significantly decreased and the production performance has been enhanced.

2.3 Hypochlorous acid leaves no residue, is non-irritating, safe and environmentally friendly

After completing the tasks of sterilization, disinfection and deodorization, hypochlorous acid will naturally degrade into water,

leaving no harmful residues in the breeding environment and causing no pollution to livestock and poultry, breeding personnel or the surrounding environment.

Compared with traditional chemical disinfectants (such as formaldehyde, glutaraldehyde, etc.), hypochlorous acid is non-toxic and odorless,

and will not cause harm to the respiratory tract, skin, etc. of livestock and poultry, nor will it corrode the breeding equipment and facilities.

This enables the hypochlorous acid generator to be used with confidence in the livestock breeding environment.

Whether it is for daily spray deodorization and disinfection in livestock and poultry houses or for the disinfection treatment of livestock and poultry drinking water,

it will not have a negative impact on the health of livestock and poultry, and at the same time ensures the food safety of the breeding products.

2.4 Hypochlorous acid has a low operating cost and significant economic benefits

The operating cost of hypochlorous acid generators is relatively low. The raw materials for its production of hypochlorous acid are mainly dilute hydrochloric acid and water. These raw materials are widely available and relatively inexpensive. Take the production of 1 liter of hypochlorous acid solution as an example. The cost is usually low. Moreover, the equipment has a long service life and the maintenance cost is not high.

Some advanced hypochlorous acid generators adopt advanced electrolysis technology and control systems, which can precisely control the generation amount

and concentration of hypochlorous acid, avoiding unnecessary waste of raw materials. In addition, as the hypochlorous acid generator can effectively improve the breeding environment, reduce the occurrence of diseases in livestock and poultry, and lower the economic losses caused by disease treatment and the death of livestock and poultry, it brings significant economic benefits to farmers in the long run.

FAQ

1,How does the hypochlorous acid generator achieve deodorization in the livestock breeding environment?

The hypochlorous acid generator produces hypochlorous acid (HClO) with strong oxidizing properties by electrolyzing salt and water.

Hypochlorous acid can rapidly undergo oxidation-reduction reactions with organic and inorganic compounds with odors

such as ammonia and hydrogen sulfide, destroying the structure of these odor molecules and decomposing them into harmless substances like water

and carbon dioxide, thereby achieving a rapid deodorization effect. Meanwhile, hypochlorous acid can also kill bacteria,

viruses and other microorganisms in the environment, reducing the odor produced by microbial metabolism from the root and purifying the breeding environment.

2,How long does it take to see obvious effects when using a hypochlorous acid generator for deodorization?

Generally speaking, after starting to use the hypochlorous acid generator to deodorize the breeding environment,

it can be notice that the intensity of the odor has weakened within 1 to 2 days. After continuous use for 3 to 7 days,

the pungent odors such as ammonia and hydrogen sulfide in most breeding farms will be significantly reduce,

and the air quality of the breeding environment will be significantly improve. However, the specific time for the effect to take effect

will be affecte by various factors such as the scale of the breeding farm, the breeding density, ventilation conditions,

and the initial odor concentration. If the breeding environment is relatively close and has a strong odor,

it may take a slightly longer time to achieve the ideal deodorization effect.

3,Compared with traditional deodorization methods, is the cost of using hypochlorous acid generators high?

In the long term, the operating cost of hypochlorous acid generators is relatively low. Traditional deodorization methods, such as spraying chemical deodorants, require continuous purchase of agents, resulting in high long-term usage costs. Moreover, some chemical agents may pose potential hazards to the health of livestock and poultry as well as the environment. The hypochlorous acid generator only consumes a small amount of salt and water as well as a certain amount of electricity to produce hypochlorous acid. The raw materials are low in cost and easy to obtain. Although purchasing equipment in the early stage requires a certain amount of capital investment, the service life of the equipment is relatively long. When calculated comprehensively, the overall cost during the usage period is often lower than that of traditional deodorization methods, and it can also bring more environmentally friendly and safe deodorization effects.