With the large-scale development of livestock breeding, the breeding problems of malodorous substances such as ammonia and hydrogen sulfide.

As well as pathogenic microorganisms in breeding farms have become increasingly prominent.

This not only affects the health and production performance of animals but may also cause environmental pollution and public health issues.

Traditional deodorization methods (such as physical adsorption, chemical oxidants, etc.) have disadvantages such as low efficiency,

high cost or secondary pollution. Hypochlorous acid generators (HCLO), as an efficient and safe disinfection and deodorization technology,

have shown remarkable application value in livestock breeding in recent years.

1,The deodorization and disinfection mechanism of hypochlorous acid

Hypochlorous acid (HOCL) is a weakly acidic small-molecule substance with extremely strong oxidizing capacity.

Its deodorization and disinfection effects are mainly achieved through the following pathways

1,1 Hypochlorous acid can decompose malodorous substances

Hypochlorous acid can directly oxidize malodorous molecules such as ammonia (NH3) and hydrogen sulfide (H2S),

converting them into odorless ammonium chloride, water or sulfate.

1,2Hypochlorous acid can kill pathogenic microorganisms

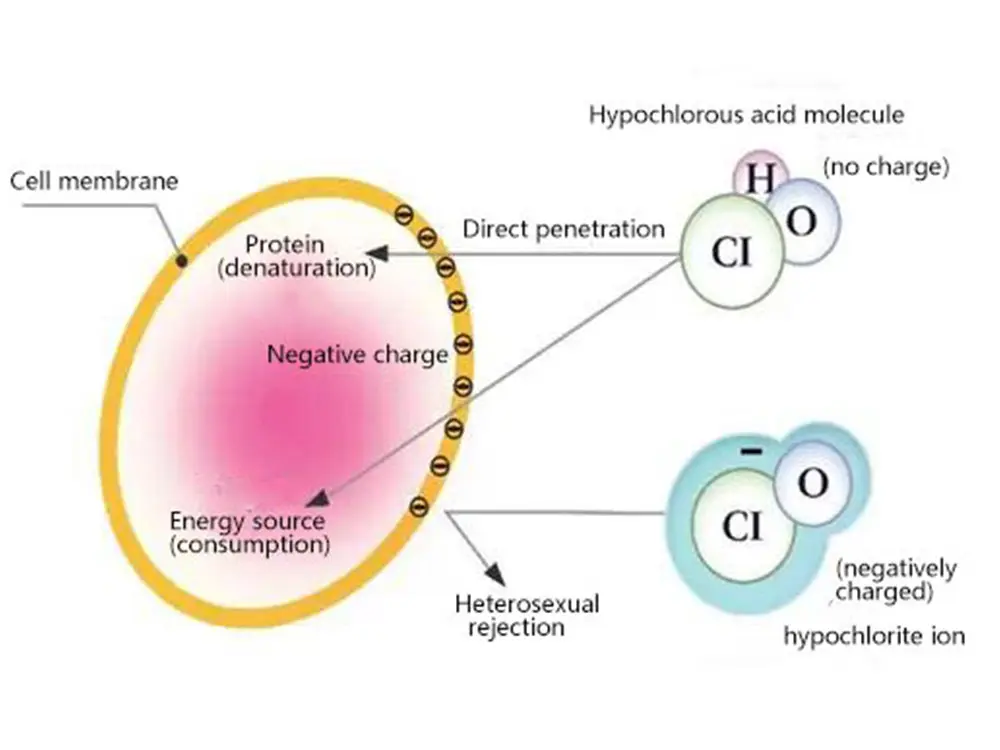

Hypochlorous acid can destroy the cell membranes or protein structures of bacteria, viruses and fungi,

reducing the odor produced by the decomposition of organic matter from the source

1,3 Hypochlorous acid can inhibit the formation of biofilms

Hypochlorous acid can prevent common microorganisms in breeding farms from adhering to the surfaces of equipment, walls, etc., reducing continuous pollution sources

2,The core advantages of hypochlorous acid generators in odor removal in aquaculture

2,1 Hypochlorous acid can effectively kill bacteria and quickly remove odors

The oxidizing capacity of hypochlorous acid is 80 times that of sodium hypochlorite (84 disinfectant).

Low-concentration hypochlorous acid (50-100PPM) can quickly neutralize malodorous substances such as ammonia and sulfides

Compared with traditional ventilation or biological deodorization, the effective time is shortened from hours to minutes,

especially suitable for sealed breeding houses

2,2 Hypochlorous acid is safe and environmentally friendly, with no residue or toxicity

Hypochlorous acid decomposes into water and trace amounts of chloride after sterilization,

leaving no irritating odor residue and avoiding damage to the respiratory mucosa of animals (commonly found in strong acid or strong alkali disinfectants).

The European Union and the US EPA have certified that hypochlorous acid can be used for the safety of food contact surfaces

2,3 Multifunctional integrated disinfection with hypochlorous acid

Hypochlorous acid can simultaneously complete disinfection and deodorization, reducing the cost of using disinfectants and deodorants separately and lowering the operational complexity

Hypochlorous acid can be used in scenarios such as air spraying, disinfection of drinking water systems, and cleaning of equipment, achieving full coverage of all links in the breeding farm

2,4 The production of hypochlorous acid is economical and practical

On-site preparation of hypochlorous acid (hypochlorous acid can be generated by electrolyzing table salt (Nacl)), with a cost of only 1/3 to 1/2 of that of chemical deodorants

The hypochlorous acid generator can adjust the concentration in real time to meet the needs of different breeding stages (such as farrowing houses and fattening houses)

2,5 Hypochlorous acid is environmentally friendly and does not pollute the environment

Disinfecting, sterilizing and deodorizing pigsties with hypochlorous acid can reduce the use of antibiotics and lower the incidence of animal diseases.

Hypochlorous acid complies with environmental protection regulations and can effectively reduce the risk of odor complaints around livestock farms

1,Why can hypochlorous acid effectively remove odors in livestock breeding?

Hypochlorous acid (HClO) has strong oxidizing properties and can rapidly undergo oxidation-reduction reactions with pungent and odorous gases

such as ammonia and hydrogen sulfide produced in livestock breeding, decomposing these odorous substances into

harmless small molecules like water and carbon dioxide. Meanwhile, hypochlorous acid can also destroy the cell membranes

and protein structures of bacteria, fungi and other microorganisms, inhibit the decomposition of organic matter by microorganisms to produce odors,

reduce the generation of odors from the source, and thus achieve efficient deodorization.

2. Is hypochlorous acid safe for animals and livestock keepers when used for deodorization in animal husbandry?

Hypochlorous acid is a mild and non-irritating disinfectant. At an appropriate dilution concentration (typically 50-200 PPM),

it has little irritation to animal skin and respiratory tracts, nor does it burn mucous membranes.

Meanwhile, hypochlorous acid decomposes to produce only water and a trace amount of salt, leaving no residue and being non-corrosive.

It will not cause damage to the breeding equipment and will not accumulate harmful substances in the animals’ bodies or the breeding environment.

However, when in use, it is still necessary to avoid direct contact of high-concentration hypochlorous acid with sensitive parts such as the animal’s eyes.

It is recommend that the keepers wear simple protective equipment during operation to ensure safe use.

3. Is hypochlorous acid suitable for all deodorization scenarios in livestock breeding? How long can the effect last?

Hypochlorous acid is suitable for various deodorization scenarios in livestock breeding, such as the interior space of livestock houses,

the ground, fences, and manure collection areas. However, for a large amount of accumulated solid feces,

it is recommend to clean them up first and then use hypochlorous acid for disinfection and deodorization to achieve better results.

The duration of the deodorizing effect of hypochlorous acid is influence by multiple factors, such as environmental humidity,

ventilation conditions, and the speed of odor generation. Generally speaking, in an environment with good ventilation and low odor generation,

the deodorization effect can last for 2 to 3 days. If the environmental humidity is high and unpleasant odors persist,

it may be necessary to use it every day or every other day to maintain a good deodorizing effect.