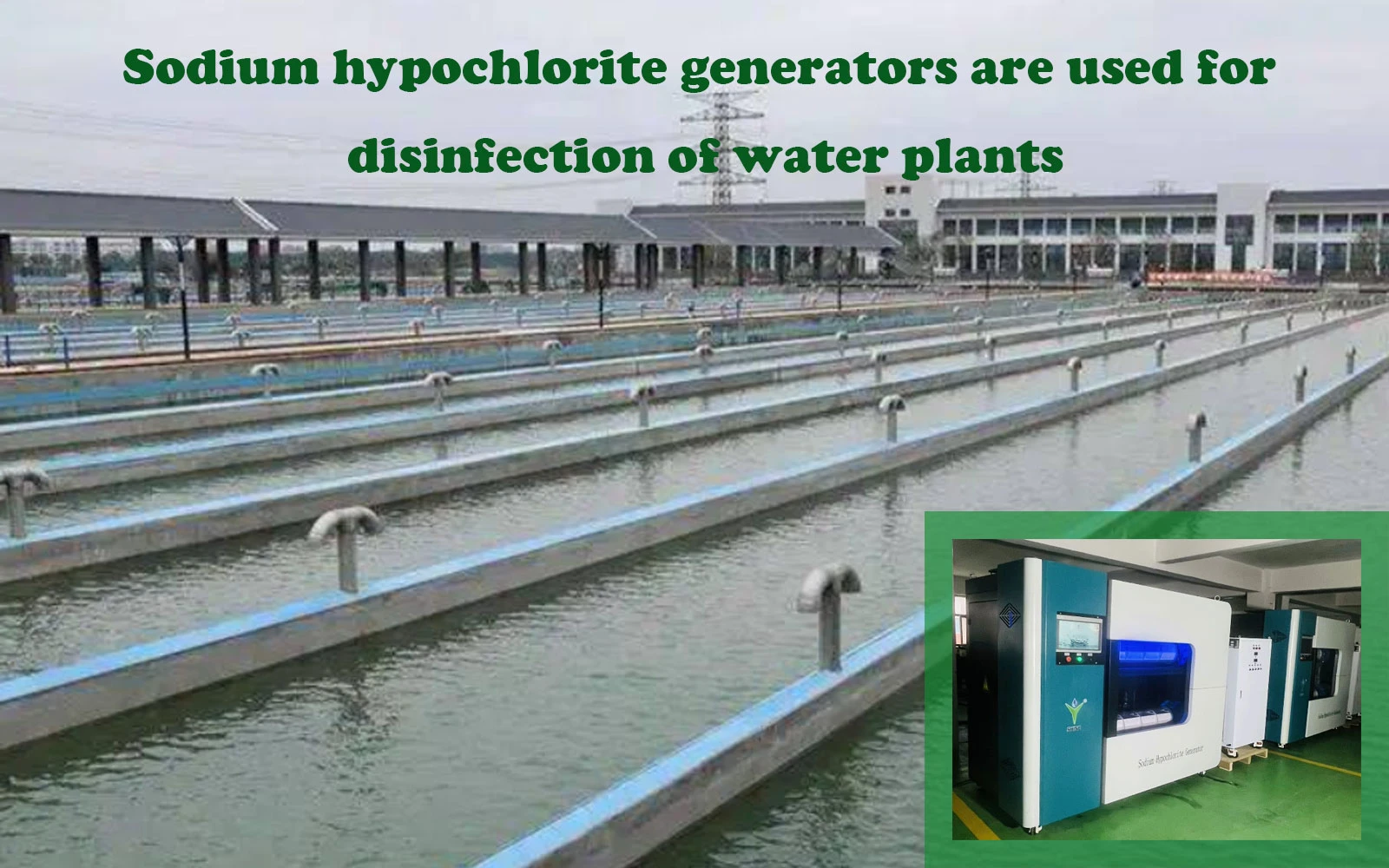

Water is the source of life, and ensuring the safety of drinking water is of Paramount importance. In the production process of waterworks, disinfection plays a key role. As an efficient and safe disinfection equipment, sodium hypochlorite generator is widely used in waterworks.

Sodium hypochlorite generator is a device that produces sodium hypochlorite solution by electrolyzing salt water. Its working principle is to electrolyze sodium chloride solution in an electrolytic cell to produce sodium hypochlorite, hydrogen and sodium hydroxide. Sodium hypochlorite has strong oxidation, which can effectively kill bacteria, viruses and other microorganisms in water. So as to ensure the health and safety of tap water.

In waterworks, the operation steps for disinfection using sodium hypochlorite generators are as follows:

First, prepare the ingredients. The salt that meets the requirements is dissolve in water to make a certain concentration of sodium chloride solution. Ensure that the purity and water quality of salt meet the requirements of the equipment to ensure the quality of sodium hypochlorite generation.

Second, start the sodium hypochlorite generator. The prepared sodium chloride solution is send to the electrolytic cell. The power is switch on, and the equipment begins to carry out the electrolytic reaction. During this process, pay close attention to the operating status of the device. Including parameters such as current, voltage, and temperature, to ensure the normal operation of the device.

Then, adjust the dosage of sodium hypochlorite. According to the flow of tap water, water quality and other factors. The dosage of sodium hypochlorite solution is precisely controlled through metering pump and other equipment. Too little dosage may not achieve effective disinfection effect, and too much dosage may have adverse effects on water quality, but also increase operating costs.

In the disinfection process, the water quality needs to be monitored in real time. By detecting the residual chlorine content and the total number of bacteria in the water. The dosage of sodium hypochlorite is adjust in time to ensure that the disinfection effect of tap water meets the national drinking water standard.

Sodium hypochlorite generator has many advantages. First of all, the sodium hypochlorite solution produced by it has a good disinfection effect and can quickly kill various pathogenic microorganisms in the water. Secondly, compared with traditional chlorine disinfection, sodium hypochlorite disinfection is more safe and reliable. And will not produce toxic and harmful by-products. In addition, sodium hypochlorite generator equipment is simple to operate, stable operation and low maintenance cost.

The operation cost of sodium hypochlorite generator disinfection equipment is low, which is one of the important reasons why it is favore by many waterworks. On the one hand, the raw materials of sodium hypochlorite generator are mainly salt and water, and the cost is relatively low. On the other hand, the energy consumption of the equipment is low, the degree of automation is high, and the manual operation cost is reduce.

Our products are available to thousands of users in more than 30 countries around the world. The wide distribution of these users fully proves the applicability and reliability of sodium hypochlorite generators in different regions and under different water quality conditions.

In short, sodium hypochlorite generator has important application value in water plant disinfection. With its advanced technology, low operating costs and high-quality services. It has made positive contributions to ensuring the safety of drinking water. With the continuous progress of science and technology and the continuous improvement of people’s requirements for drinking water quality. Sodium hypochlorite generator will certainly play a more important role in the field of water plant disinfection.