Introduction

Clean, safe drinking water is essential. Therefore, many small water plants struggle with disinfection challenges. However, traditional chlorine gas and low-concentration hypochlorite solutions pose risks. Meanwhile, our sodium hypochlorite generator (6000-8000ppm) offers a safer, more efficient alternative.

This case study explores how a small water plant improved disinfection, reduced costs, and also enhanced safety with our system.

Project Overview

Location & Challenge

Location: Rural community water plant (serving 5,000 residents)

Previous System: Chlorine gas cylinders (high risk, unstable supply)

Issues:

Safety hazards (toxic gas leaks)

Frequent transportation and also handling risks

Inconsistent chlorine dosing

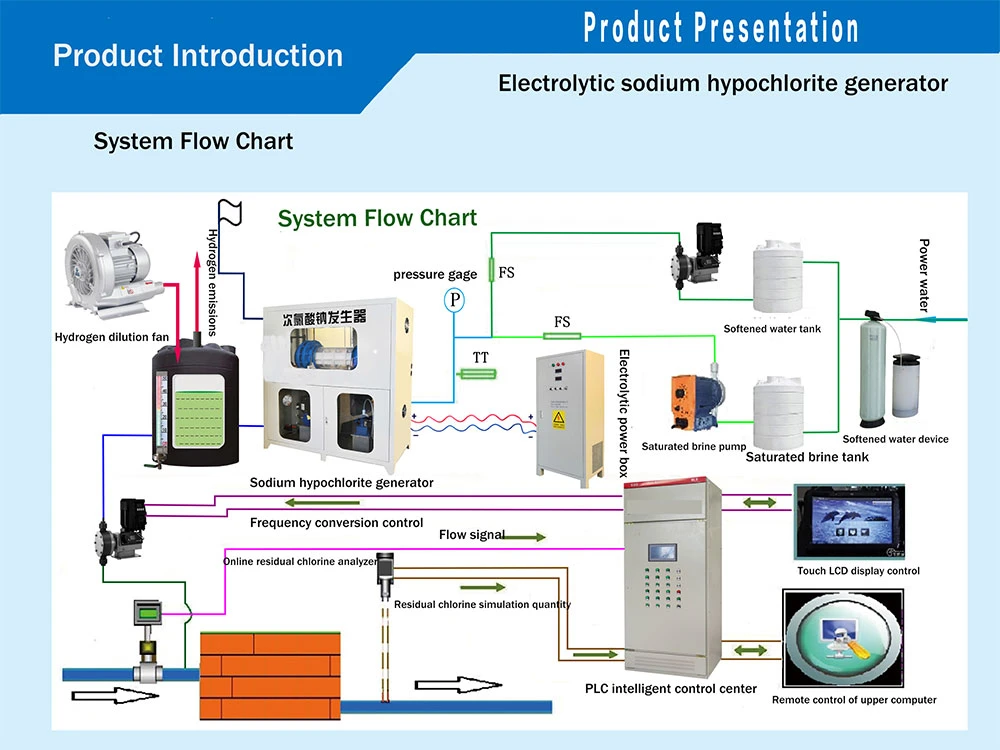

Solution: On-Site Sodium Hypochlorite Generation

We installed a compact, concentration (6000-8000ppm) sodium hypochlorite generator.

Key features:

High concentration – Stronger than typical 1% solutions, reducing storage needs

On-demand production – No reliance on external suppliers

Safe operation – No hazardous gas risks

Automated dosing – Precise residual chlorine control

Advantages:

Less storage space – Higher concentration means smaller tanks

Longer shelf life – Degrades slower than diluted solutions

Lower transport costs – Produce on-site, no bulk deliveries

Better disinfection power – More effective against bacteria & viruses

Installation & Performance

Installation Process

Site assessment – Evaluated water demand and existing infrastructure.

System setup – Installed generator, salt dissolver, and dosing pumps.

Training – Staff learned operation and also maintenance in one day.

Operational Results

Disinfection efficiency: 99.9% pathogen kill rate

Cost savings: 30% lower than chlorine gas

Maintenance: Minimal, only salt and also electrode cleaning required

Safety: Zero gas leaks or chemical spills

FAQs

1. How often must we replace the salt?

Depends on usage. For this plant, 1-ton salt bags last 2-3 months.

2. What’s the power consumption?

Low energy use—about 4.5 kWh per kg of chlorine produced.

3. Can the system adjust to varying water demand?

Yes. Meanwhile, fully automated dosing adjusts based on flow rate and chlorine demand.

Conclusion

Then switching to concentration sodium hypochlorite (6000-8000ppm) transformed this small water plant.

Key benefits:

Safer – No toxic gas risks

Cheaper – Lower operational costs

More reliable – On-site production ensures supply

Stronger disinfection – Concentration improves water safety

For small water plants seeking a cost-effective, safe, and also efficient disinfection solution, our sodium hypochlorite generator is the ideal choice.