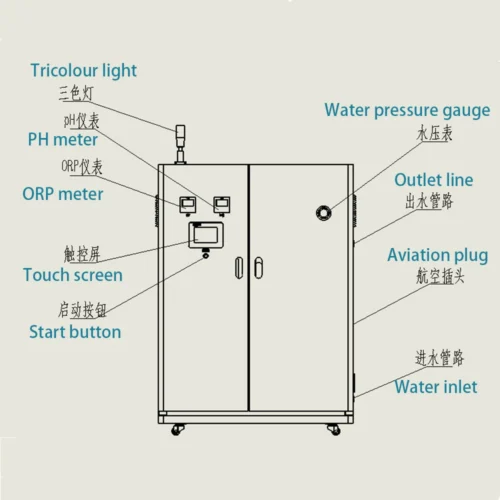

| Product name | SHC-1000 |

|---|---|

| Flow | 1000L/H |

| Concentration | 50-500PPM(adjustable) |

| PH | 2-6.5 |

| ORP | >1100mv |

| Electrolyzer | HCL |

| Voltage | 220/50 |

Product introduction-HOCL

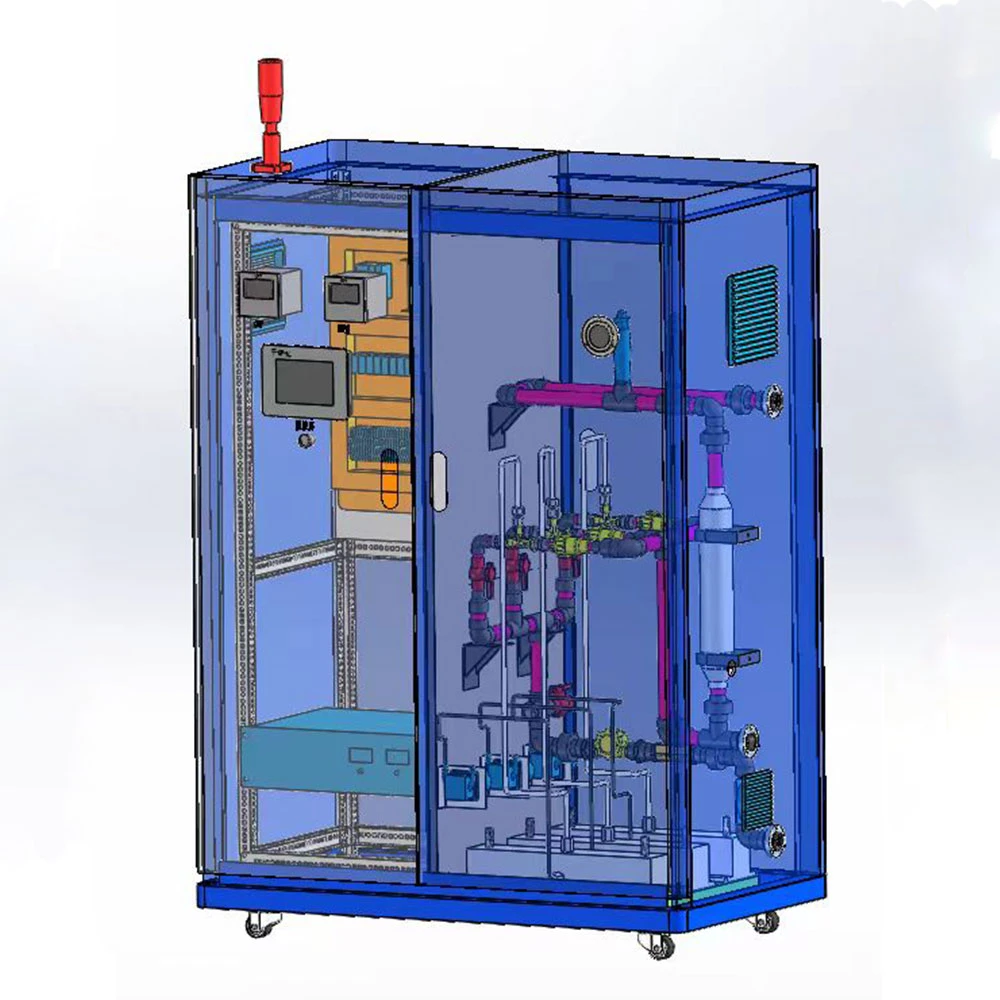

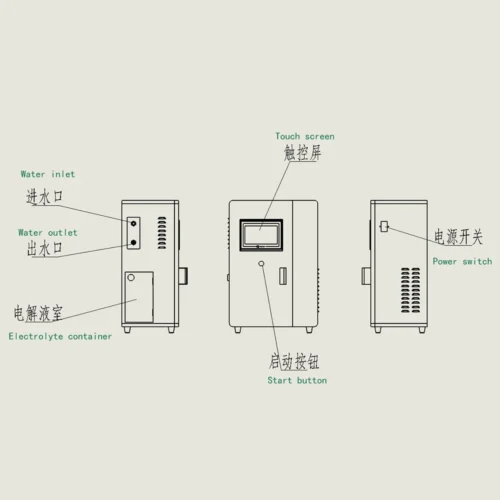

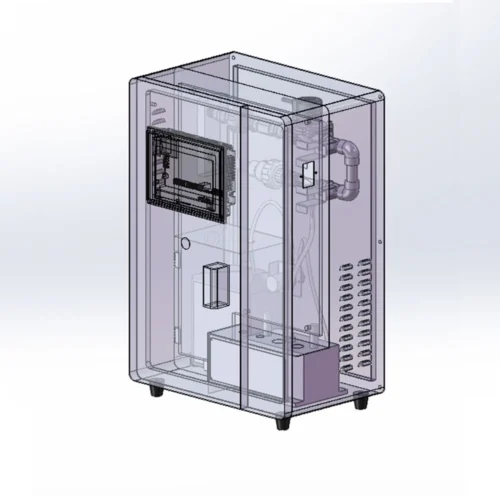

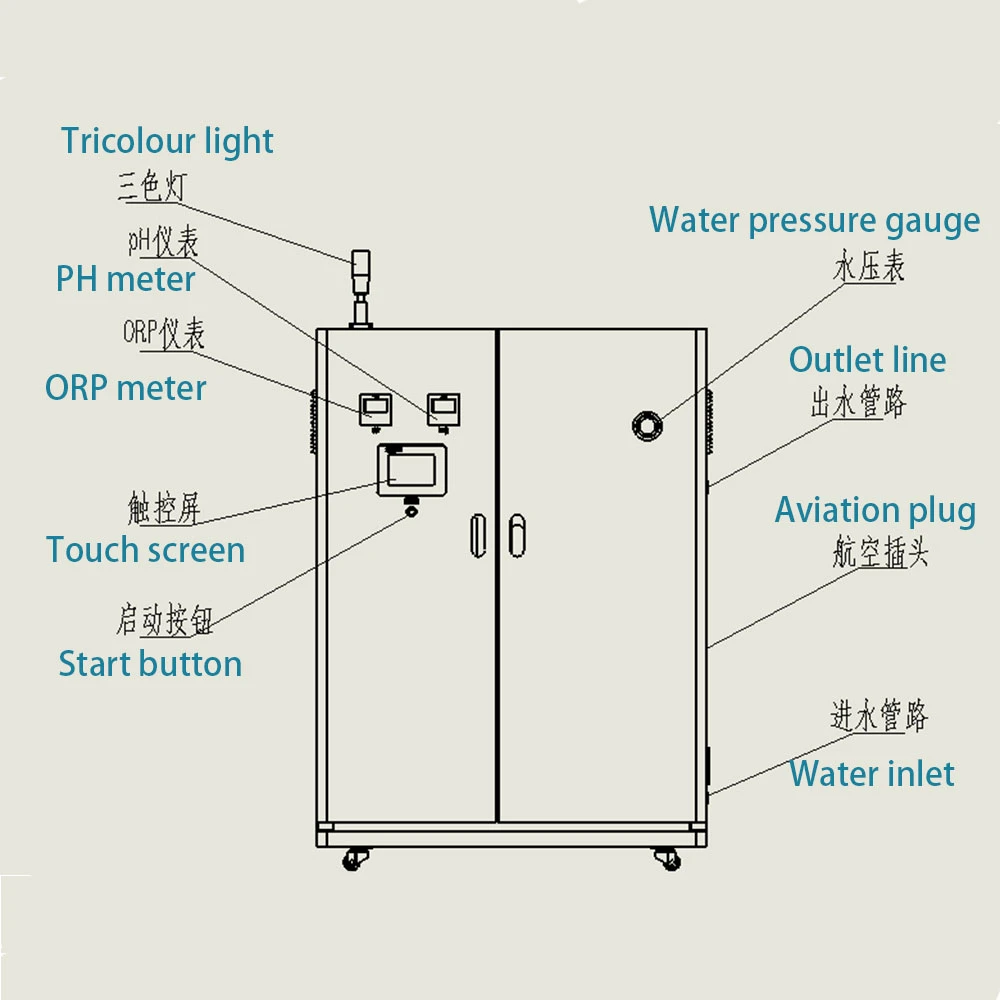

1. PLC touch screen control, industrial control system, stable and reliable performance;

2. Liquid level detection function, water flow detection feedback, electromagnetic water valve sensor feedback, with fault alarm feedback;

3. Real-time online monitoring, 4G Internet of Things module, convenient for customers to remotely operate and view equipment operating status, timely understanding of equipment operating status;

4. ORP and pH online real-time monitoring function, timely feedback machine operation data;

5. Data preservation: the equipment records the operating data, which is easy for customers to trace and understand;

6. The electrolytic cell adopts imported ruthenium-iridium coating, unique structural design + program setting, to ensure stable electrolytic work, less liquid consumption, energy saving and economy;

7. Equipment output is pure hypochlorous acid water, no other impurities, no stabilizer added. The liquid concentration is stable, environmentally friendly and harmless after degradation.

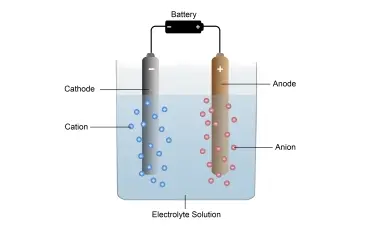

Electrolysis Technology – Generating Hypochlorous Acid (HOCl)

Invention of Electrolysis

Electrolysis is the passing of a direct electric current through an ionic substance. It was first explained by Michael Faraday in the 1830s.

Membrane Electrolysis

Membrane electrolysis generates strongly acidic HOCl and an alkaline byproduct of NaOH from a solution of NaCl (aka. table salt in water).

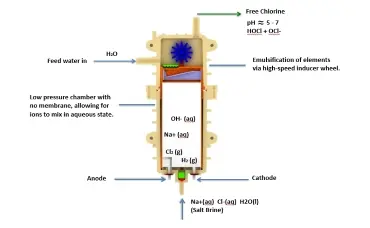

Single Cell Electrolysis

Single cell technology was developed to generate a more stable solution of HOCl at an optimal pH without an alkaline byproduct of NaOH.

Healthcare

Hypochlorous acid (HOCl) is already produced by the white blood cells in our blood for protecting against invading microbial pathogens.

Food Safety