What makes this generator different?

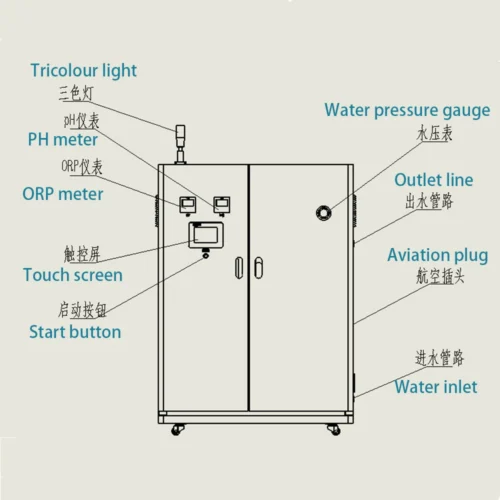

Titanium Electrolysis Cell – The cell is manufactured with a high grade titanium coating. Systems using electrolysis cells that are manufactured from lower quality alloys will deteriorate quickly and may not be generating hypochlorous acid. If the electrolysis cell is made from steel or other lower grade metals, the electrolysis cell will deteriorate very quickly and will generate harmful chromium compounds that can be carcinogenic.

Size of the Electrolysis Cell – Our electrolysis cell is relatively large for a 1 Liter pitcher and only requires 2 grams of salt to generate 200 ppm of hypochlorous acid. Even higher concentrations can be generated if the system is run for extra cycles. Many low quality systems manufactured in China are requiring very large quantities of salt. If you see that the directions on a system require 5 to 20 grams of salt per Liter, you can be sure that the electrolysis cell is very small and your solution salinity will be extremely high. Most likely the system is generating sodium hypochlorite (NaOCl) and not hypochlorous acid (HOCl)

Electrolysis Technology – Generating Hypochlorous Acid (HOCl)

Invention of Electrolysis

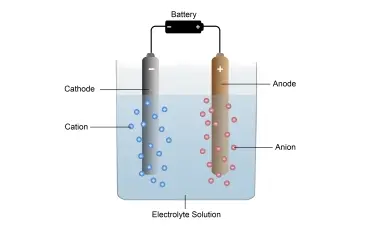

Electrolysis is the passing of a direct electric current through an ionic substance. It was first explained by Michael Faraday in the 1830s.

Membrane Electrolysis

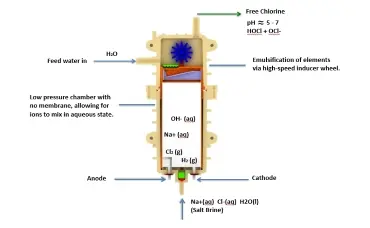

Membrane electrolysis generates strongly acidic HOCl and an alkaline byproduct of NaOH from a solution of NaCl (aka. table salt in water).

Single Cell Electrolysis

Single cell technology was developed to generate a more stable solution of HOCl at an optimal pH without an alkaline byproduct of NaOH.

Healthcare

Hypochlorous acid (HOCl) is already produced by the white blood cells in our blood for protecting against invading microbial pathogens. When microbial pathogens try to enter a wound, white blood cells are the first responders and engulf the bacteria exposing them to the biocide HOCl. Because HOCl is non-irritant and gentle on skin, it makes sense to use it for wound care. In addition, it can replace all general sanitation chemicals used to clean healthcare facilities. Eliminating toxic chemicals not only makes sense but provides a safer environment for children and the elderly.

Food Safety

The majority of the research that has been done regarding the practical applications of hypochlorous acid has been in the field of food safety. Since the Food Safety Modernization Act (FSMA) was signed into law in 2011, the focus of food safety has shifted from responding to contamination to preventing it. There is probably no food sanitizer more researched and more understood than hypochlorous acid. The research clearly demonstrates that hypochlorous acid is safe and efficient for ensuring microbial counts are maintained below infectious levels on food and contact surfaces.