Hypochlorous acid generators have shown great potential in the field of food processing, cleaning and

preservation due to their unique working principle and significant application advantages. From the cleaning of fruits and vegetables to

the processing of meat and aquatic products, and then to the disinfection of equipment and the environment,

hypochlorous acid generators provide comprehensive support in ensuring food safety, extending the shelf life of food,

improving food quality, and reducing the operating costs of enterprises. They are gradually

becoming a capable assistant in the food processing industry, promoting the development

of the food processing industry towards a safer, more efficient and environmentally friendly direction.

1,The application of Hypochlorous acid in Food Processing, Cleaning and preservation

The application of hypochlorous acid in the Cleaning of fruits and vegetables

1.1 Highly efficient sterilization and disinfection: Hypochlorous acid has strong oxidizing properties and can quickly destroy the cell walls,

cell membranes, internal enzyme systems and genetic materials of bacteria, viruses, fungi and other microorganisms,

thereby efficiently killing common harmful bacteria on the surface of fruits and vegetables, such as Escherichia coli,

Staphylococcus aureus, Salmonella, etc. Studies show that washing fruits and vegetables with

hypochlorous acid solution can reduce the number of microorganisms by more than 99%,

significantly lowering the risk of diseases caused by consuming contaminated fruits and vegetables, and effectively ensuring food safety.

1.2 Removal of pesticide residues: The strong oxidizing property of hypochlorous acid can decompose various pesticides remaining on the surface of fruits and vegetables,

such as organophosphorus and pyrethroids. It can disrupt the chemical structure of pesticide molecules,

converting them into relatively harmless substances and significantly reducing the harm of pesticide residues ingested by the human body.

For instance, after being treated with hypochlorous acid solution, the residue levels of certain organophosphorus pesticides

can be reduce by over 80%, effectively enhancing the edible safety of fruits and vegetables.

1.3 Maintain color and taste: Some traditional cleaning methods may have a certain impact on the color and taste of fruits and vegetables.

Hypochlorous acid solution is mild in nature. While effectively cleaning and sterilizing, it can maintain the original color and

tender taste of fruits and vegetables to the greatest extent. This is because hypochlorous acid does

not damage the cellular structure of fruits and vegetables like some strongly alkaline cleaning agents do, thus ensuring the quality of fruits and vegetables.

2,The application of hypochlorous acid generators in the fields of meat and aquatic product processing

2.1,Sterilization and preservation: Meat and aquatic products are rich in protein and water,

and are highly susceptible to microbial contamination and spoilage. The hypochlorous acid solution produced by

the hypochlorous acid generator can be used for soaking or spraying disinfection of meat and aquatic products,

effectively killing harmful microorganisms on the surface, inhibiting bacterial growth, and extending the shelf life of the products.

For instance, in seafood processing, after being treated with hypochlorous acid, the shelf life of seafood can be extended by 2 to 3 days,

reducing economic losses caused by spoilage.

2.2. Inhibiting the generation of odors: Hypochlorous acid can oxidize and decompose the odor substances produced during the storage of meat and aquatic products,

such as trimethylamine and hydrogen sulfide, thereby effectively inhibiting the generation of odors, maintaining the good smell of the products,

and enhancing the purchasing experience of consumers.

3.3,Blood water purification: During the meat processing, a large amount of wastewater containing blood water and impurities is produced.

Hypochlorous acid solution can be used to purify these blood waters. It can kill the microorganisms in the blood water,

reduce the organic matter content in the sewage, alleviate the burden of subsequent sewage treatment,

and at the same time reduce the unpleasant odor caused by the spoilage of the blood water.

The application advantages of hypochlorous acid generators

1, No residue during installation

Hypochlorous acid will gradually decompose into water and oxygen after sterilization and disinfection,

and will not leave harmful residues on the surface of food or in the processing environment.

This is in sharp contrast to traditional disinfectants such as sodium hypochlorite. If traditional disinfectants are not thoroughly clean,

they may lead to excessive residual chlorine, posing a potential threat to human health.

The hypochlorous acid produced by the hypochlorous acid generator is used in food processing and fully complies with food safety standards.

Consumers do not need to worry about chemical residues, ensuring the safety and quality of food.

2, Highly efficient sterilization

Hypochlorous acid has broad-spectrum bactericidal properties and has a significant killing effect on almost all common pathogenic microorganisms,

including bacteria, viruses, and fungi. Its sterilization speed is fast, usually achieving the ideal sterilization effect within a few seconds to several minutes. Compared with some other disinfection methods, it greatly shortens the disinfection time and improves production efficiency. For instance, in the food processing in the central kitchen, rapid and efficient sterilization and disinfection can ensure that food is process and delivered in a timely manner, meeting market demands.

3,High cost-effectiveness

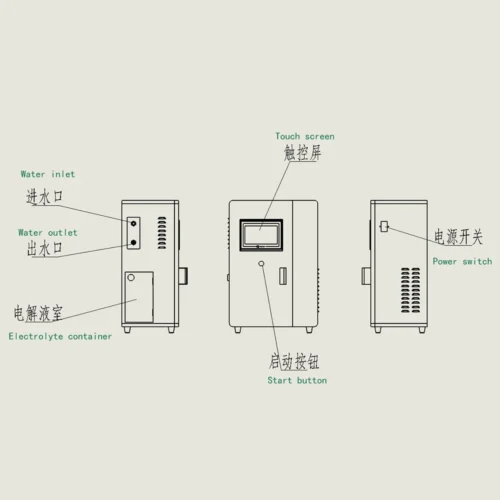

The operating cost of a hypochlorous acid generator is relatively low. Its main raw materials are salt and water, and hypochlorous acid is produce through electrolysis, eliminating the need to purchase expensive chemical disinfectants. Moreover, due to the high efficiency of hypochlorous acid, the usage amount is relatively small, further reducing the cost. Meanwhile, hypochlorous acid is non-corrosive to equipment, reducing the frequency of equipment maintenance or replacement due to corrosion. In the long run, it lowers the overall operating costs of enterprises. For instance, in large food processing plants, the use of hypochlorous acid generators for daily disinfection can save a significant amount of disinfectant procurement costs and equipment maintenance expenses every year.

4,Green and environmentally friendly

The decomposition products of hypochlorous acid are water and oxygen, which cause no pollution to the environment and are in line with the current green and environmentally friendly development concept. Against the backdrop of the food processing industry’s increasing emphasis on environmental protection, the application of hypochlorous acid generators helps enterprises reduce their negative impact on the environment and achieve sustainable development. Compared with the possible environmental pollution caused by traditional disinfectants during production, transportation and use, hypochlorous acid generators offer a more environmentally friendly disinfection solution for food processing enterprises.

FAQ

What concentration of hypochlorous acid should be used in food processing and cleaning?

The concentration to be used depends on the specific application. For the disinfection of fruits, vegetables, fish, seafood and other foods, a concentration of 20-30 ppm is very effective. However, the US Food and Drug Administration (FDA) allows a concentration as high as 60 ppm without the need for post-event rinsing. For the disinfection of food contact surfaces, a concentration of 20-30 ppm is also effective, but the US Food and Drug Administration (FDA) allows a concentration as high as 200 ppm. For water disinfection, a concentration of 1-2 ppm is effective, but the United States Environmental Protection Agency (EPA) allows a concentration as high as 4 ppm.

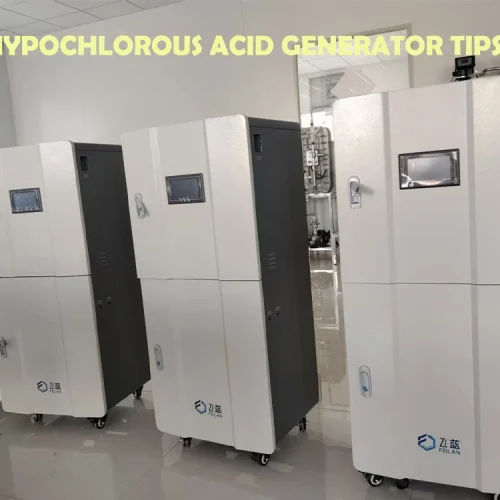

Factory strength

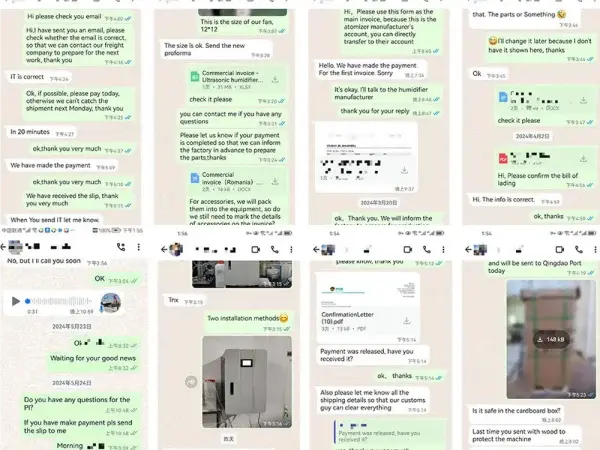

Customer feedback