In the field of livestock breeding, the odor problem in breeding farms has always been a major challenge for practitioners.

1:The manure, urine, sewage, bedding and feed residues of livestock and poultry can all produce unpleasant odors,

which not only affect the working environment of the breeders, reduce their work enthusiasm and efficiency,

but also may cause disturbances to the lives of the surrounding residents and trigger neighborhood conflicts.

2:More importantly,a bad odor environment can have a negative impact on the health and growth performance of livestock and poultry,reducing the efficiency of breeding.

3:For instance, high concentrations of ammonia can irritate the respiratory mucosa of livestock and poultry,

leading to the occurrence of respiratory diseases, reducing their immunity and making them more vulnerable to the invasion of other pathogens.Therefore, it is extremely urgent to effectively solve the deodorization problem in livestock farms.

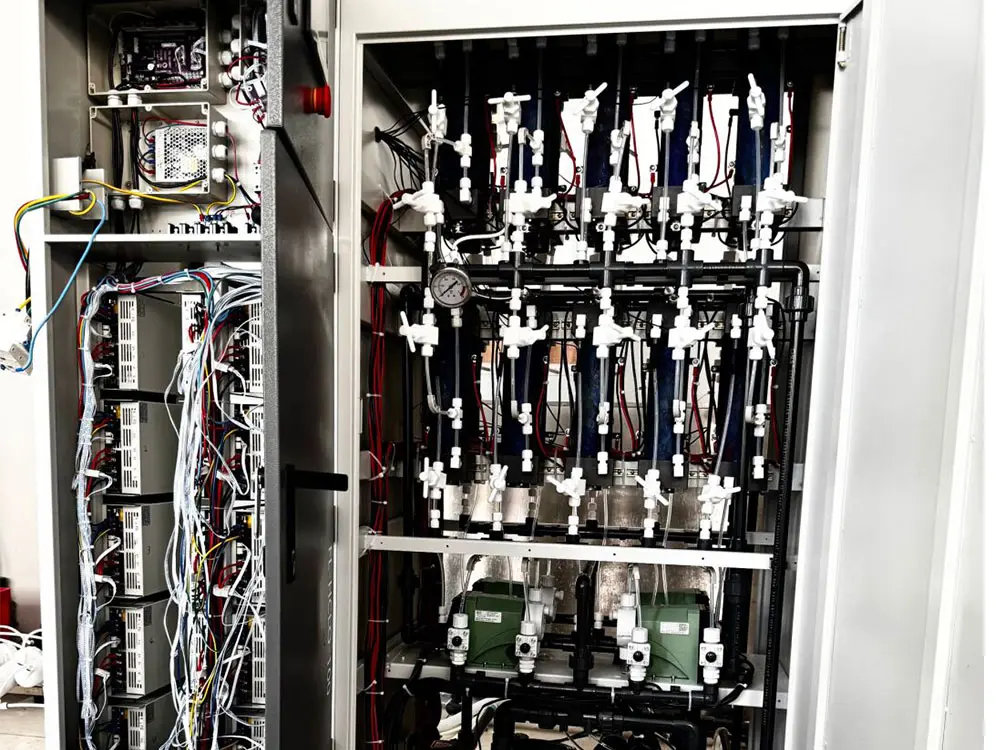

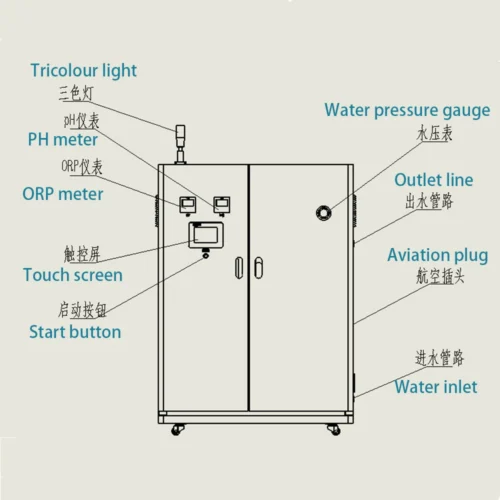

| Product name | Large hypochlorous acid generator equipment specifically designed for livestock breeding |

|---|---|

| concentration | 50-500PPM(Adjustable) |

| Flow rate | 5000L/H |

| PH of acidic water | 5-6.5 |

| Electrolyte | salt(Nacl) or Hydrochloric acid(HCL 5%) |

| Power | 6200W |

| Concentration | 380V/50Hz |

| Size | 70cm*60cm*175cm |

The working principle and deodorization mechanism of hypochlorous acid generators

Hypochlorous acid generators usually produce hypochlorous acid (HClO) solution by electrolyzing brine.

1:During the electrolysis process,the sodium chloride (NaCl) solution undergoes a series of chemical reactions through the action of

electrodes in a specific electrolytic cell,ultimately generating a disinfectant solution containing hypochlorous acid. The main reaction process is as follows:

At the anode, chloride ions (Cl⁻) lose electrons and are oxidized to form chlorine gas (Cl₂), and chlorine gas reacts with water to

produce hypochlorous acid and hydrochloric acid. At the cathode, water molecules gain electrons to generate hydrogen gas (H₂)

and hydroxide ions (OH⁻). By precisely controlling the electrolysis conditions, such as current, voltage, and electrolysis time,

hypochlorous acid solutions of different concentrations can be obtained to meet various application requirements.

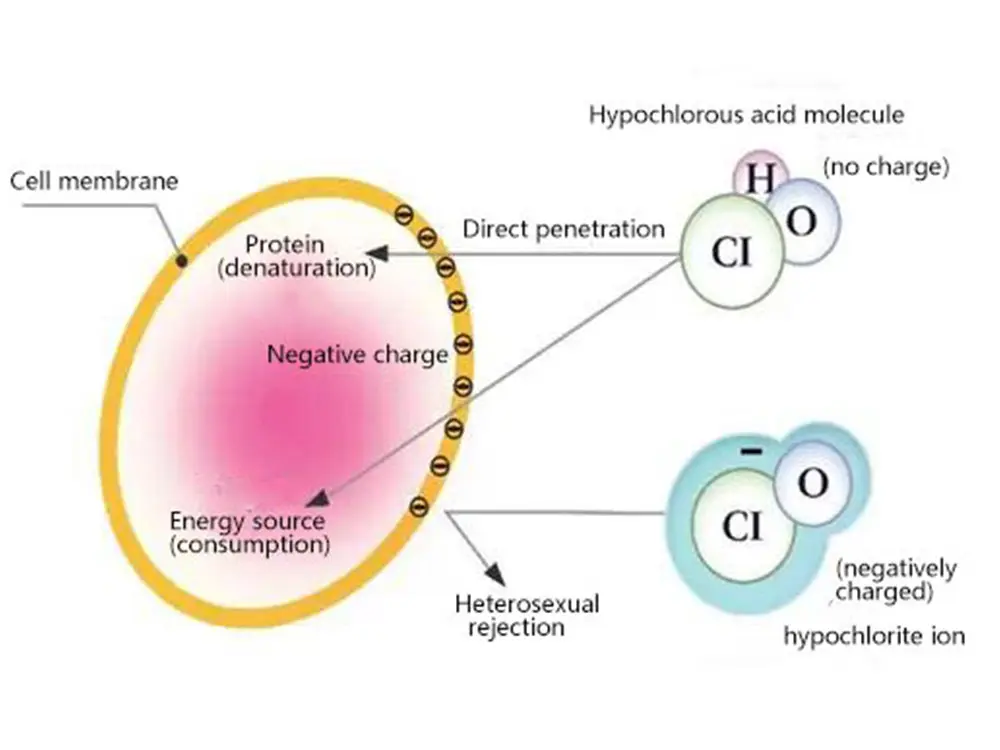

2:The reason why hypochlorous acid has a powerful deodorizing ability is based on its unique chemical properties.

Hypochlorous acid is a strong oxidant with a high REDOX potential, capable of undergoing chemical reactions with various odor molecules.

In livestock farms, the main odor components include ammonia (NH₃), hydrogen sulfide (H₂S), methyl mercaptan (CH₃SH), etc.

Take ammonia as an example. Hypochlorous acid can oxidize ammonia to nitrogen (N₂) and water,

and the reaction equation is: 3HClO + 2NH₃ = N₂ + 3HCl + 3H₂O. For hydrogen sulfide, hypochlorous acid oxidizes it to sulfate ions (SO₄²⁻) and water,

with the reaction as follows: 4HClO + H₂S = H₂SO₄ + 4HCl. Through these oxidation reactions, hypochlorous acid can convert odor molecules with

pungent odors into harmless or low-odor substances, thereby achieving a significant deodorization effect.

Lorem ipsum dolor sit amet...

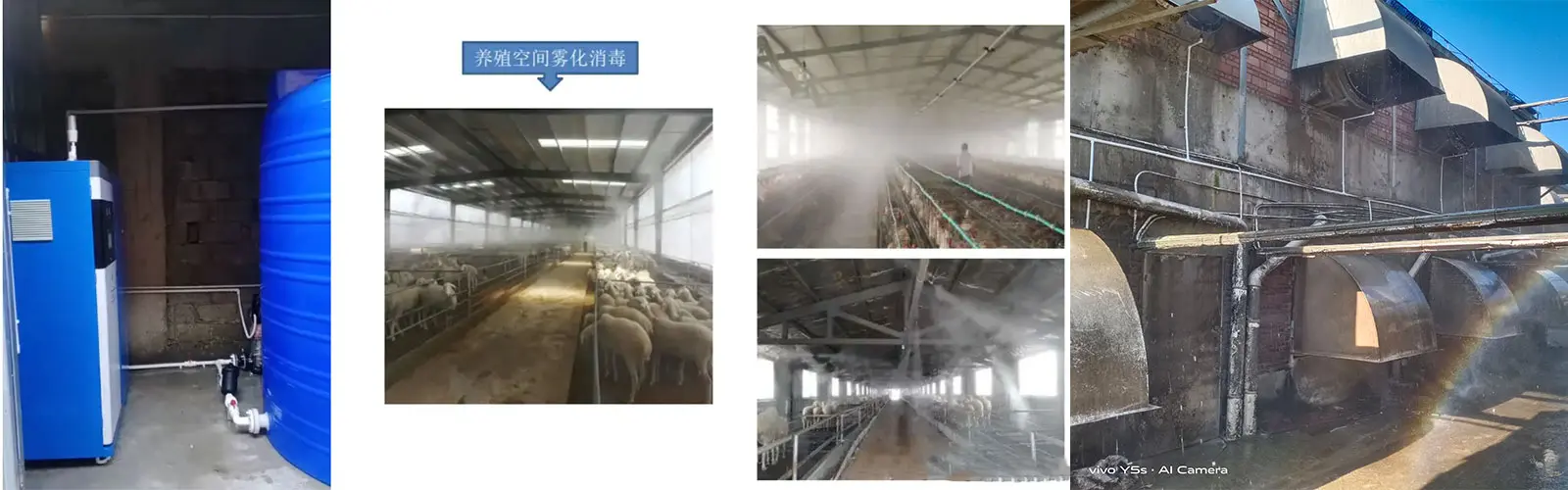

Deodorization with hypochlorous acid in the pigsty environment

Due to the large number of pigs in the pigsty, a large amount of manure and urine is produced. If not cleaned up in time, a large amount of ammonia

and other foul odors will be generated rapidly. Install the hypochlorous acid generator at an appropriate position in the pigsty,

regularly produce hypochlorous acid solution, and evenly spray it on the air, ground, walls and other surfaces of the pigsty through the spray system.

The particle size of the spray should be controlled within an appropriate range, generally between 50 and 150 microns,

which can ensure that hypochlorous acid can fully contact and react with the odor molecules in the air. Studies show that after a period of use,

the ammonia concentration in the pigsty can be reduced by 50% to 70%, significantly improving the air quality in the pigsty,

reducing respiratory diseases in pigs caused by ammonia stimulation, and increasing the growth rate and feed conversion rate of pigs.

For instance, a large-scale pig farm adopted hypochlorous acid generators to deodorize the pigsty. Within one month after its use,

the incidence of respiratory diseases among the pigs decreased by 30%, and the average daily weight gain increased by about 10%.

The application of Hypochlorous acid in Deodorization of Fecal treatment areas

The manure treatment areas of pig farms, such as biogas digesters and manure storage tanks, are the concentrated areas where odors are produce.

The high-concentration hypochlorous acid solution (generally with a concentration of 200-500 PPM) produced by the

hypochlorous acid generator can be transporte through pipelines to the manure treatment area for regular spraying or

direct addition to the manure. Near the feed and discharge ports of the biogas digester, spraying hypochlorous acid solution

at regular intervals every day can effectively inhibit the generation of odors during the fermentation process of manure.

For septic tanks, hypochlorous acid solution can be adde to the tank in a certain proportion to allow the hypochlorous acid to fully

react with the organic matter in the fecal sewage, reducing the volatilization of odors such as ammonia and hydrogen sulfide.

After treatment, the odor concentration around the fecal sewage treatment area was significantly reduce,

and the impact on the surrounding environment was greatly decrease.

The advantages of hypochlorous acid generators in deodorization in livestock breeding

1:Hypochlorous acid has broad-spectrum bactericidal properties and can quickly kill common pathogens in livestock farms,

such as Escherichia coli, Staphylococcus aureus, Salmonella, etc., with a bactericidal rate of over 99%. Meanwhile,

it has a strong decomposition ability for odor molecules such as ammonia and hydrogen sulfide, and the deodorization effect is remarkable.

2:Compared with traditional deodorants, hypochlorous acid generators can reduce the odor concentration in the breeding farm in a shorter time

and have a longer duration of effect. For instance, traditional physical adsorption deodorants,

3:such as activated carbon,can adsorb odor molecules to a certain extent. However, as time goes by and the adsorption reaches saturation,

the deodorization effect will be greatly reduce. In contrast, hypochlorous acid generators can continuously produce

hypochlorous acid to constantly decompose and treat the odor.

Company strength

Case client

Delivery status