The hypochlorous acid generator can prepare hypochlorous acid solution on site, eliminating the need to

purchase and store large quantities of finished disinfectant solutions, thus reducing transportation and storage costs.

Meanwhile, due to the remarkable bactericidal effect of hypochlorous acid, it can enhance production efficiency

and reduce product loss caused by microbial contamination during the production process of cosmetics.

Hypochlorous acid generators bring higher cost benefits to the cosmetics industry and help improve the competitiveness of cosmetics.

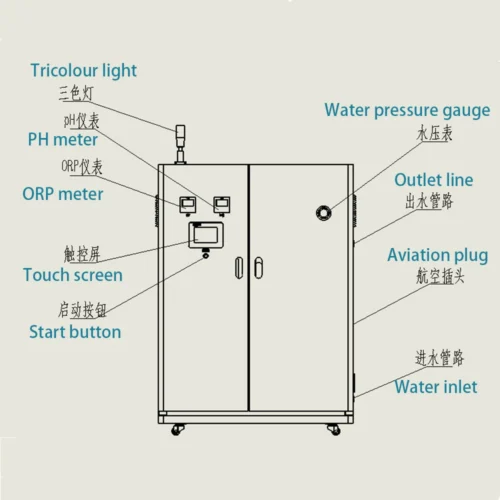

Parameters of hypochlorous acid generator equipment

| Product name | Hypochlorous acid generators are used in the cosmetics industry |

|---|---|

| Concentration | 10-1000PPM(Adjustable) |

| Flow rate | 1000L/H |

| PH | 5.0-6.5 |

| Electrolyte | salt (Nacl) or hydrochloric acid (5% HCL) |

| Power | 6200W |

| Voltage | 380V/50Hz |

| Size | 70*60*175cm |

Application scenarios of hypochlorous acid generators in cosmetic production

1,Disinfection of production equipment and workshop environment

The cleaning and disinfection of cosmetic production equipment are of vital importance, as they are related to product quality and consumer safety.

The hypochlorous acid produced by the hypochlorous acid generator can efficiently disinfect various equipment on the production line,

such as mixing tanks, filling machines, pipelines, etc. Hypochlorous acid can quickly kill bacteria, viruses and fungi adhering to the surface of equipment,

prevent microorganisms from breeding and multiplying in the crevices or dead corners of the equipment, and avoid contaminating the cosmetics produced subsequently

Meanwhile, the hygiene conditions of the workshop environment directly affect the microbial indicators of the products.

Using hypochlorous acid water generated by a hypochlorous acid generator to disinfect the workshop floor, walls, doors,

Windows and air by spraying or wiping can create a clean production environment, reduce the risk of microbial contamination

and ensure that cosmetics are produced in a space that meets hygiene standards.

2,Disinfection of raw materials and packaging materials with hypochlorous acid

There are various types of cosmetic raw materials, and some natural raw materials may carry microorganisms.

Hypochlorous acid generators can be used for pre-treatment and disinfection of raw materials. For instance,

during the raw material preparation process, an appropriate amount of hypochlorous acid can be add to the water to purify the

water source and remove any harmful microorganisms that may exist in the water, ensuring the purity of the raw materials.

For some solid raw materials, surface disinfection can also be carried out by spraying hypochlorous acid to

prevent microorganisms from entering the product during the raw material mixing process

Packaging materials should not be overlook either. From plastic bottles, glass bottles to paper boxes, etc.,

they are prone to microbial contamination during storage and transportation. Soaking or spraying hypochlorous acid solution

to disinfect packaging materials can effectively kill the microorganisms on the packaging surface, avoid secondary pollution to cosmetics during filling and packaging,

and extend the product’s shelf life

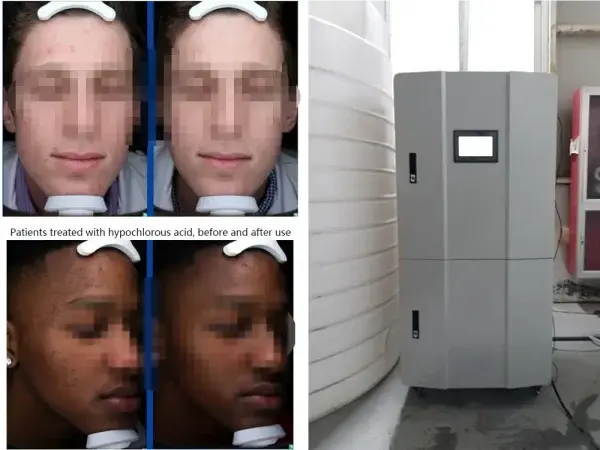

3,Hypochlorous acid can be used as an additive in cosmetics

Hypochlorous acid is gradually being use in cosmetic formulas due to its unique skin care effects. Adding an appropriate amount of

hypochlorous acid to some facial cleansers can enhance the cleansing effect, effectively remove dirt, excess oil and bacteria on the skin surface,

prevent the formation of acne and blackheads, and at the same time maintain the skin’s acid-base balance, making the skin fresh, clean and not tight.

Adding hypochlorous acid to products such as toners, lotions and creams can take advantage of its antioxidant and skin-soothing properties to neutralize free radicals,

reduce the damage of oxidative stress to the skin and delay skin aging. It can also alleviate skin inflammatory reactions, relieve skin allergies,

itching and redness and swelling, improve the product’s suitability for sensitive skin, and enhance the comprehensive skin care effect of the product

Company strength

Shipping capacity

FAQ

1,In what aspects does your company's core competitiveness lie?

Independent research and development strength: The R&D team accounts for 30%, with 68 patented technologies (such as core algorithms/processes in the XX field),

and the product iteration speed has maintained an average of two major upgrades per year in the past three years.

2,What is the shipping cycle for regular orders? Is there an express lane?

In-stock products: Goods will be dispatch within 1 to 4 working days after placing an order and making payment

Customized products: Depending on the complexity of the requirements, it usually takes 7 to 15 working days