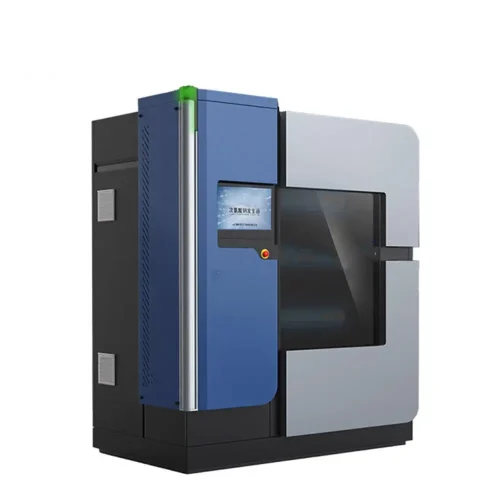

How It Works

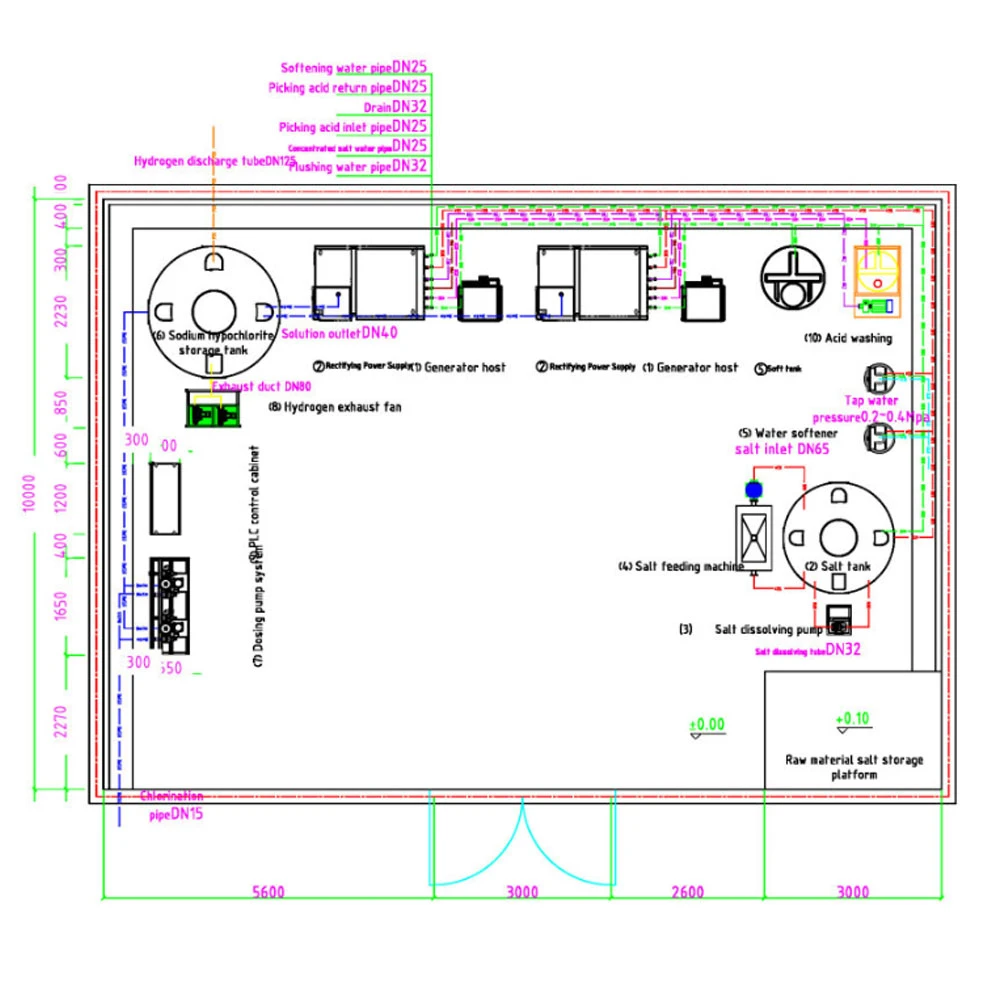

First and foremost, let’s take a look at how our Sodium Hypochlorite Generator functions. It operates on a simple yet highly efficient principle. The generator uses a process of electrolysis. When an electric current is passed through a brine solution (a mixture of salt and water), a chemical reaction occurs. Chlorine gas is produced at the anode, and sodium hydroxide is formed at the cathode. These two by – products then react with each other to form sodium hypochlorite, the main disinfectant in our water treatment solution. This in – situ production method ensures that the sodium hypochlorite is always fresh and at its peak effectiveness.

Ideal for Multiple Applications

Our Sodium Hypochlorite Generator is incredibly versatile and suitable for a wide range of applications. For instance, in municipal water treatment plants, it plays a vital role in disinfecting large volumes of water. It effectively kills harmful bacteria, viruses, and other pathogens, making the water safe for consumption. In industrial settings, such as food and beverage factories, pharmaceutical plants, and power generation facilities, the generator is used to treat process water. It helps maintain the quality of the water used in manufacturing processes, preventing contamination and ensuring product integrity. Additionally, it is an excellent choice for swimming pool and spa water treatment. By regularly adding the freshly generated sodium hypochlorite, the water remains clean, clear, and free from algae and bacteria, providing a safe and enjoyable swimming environment.

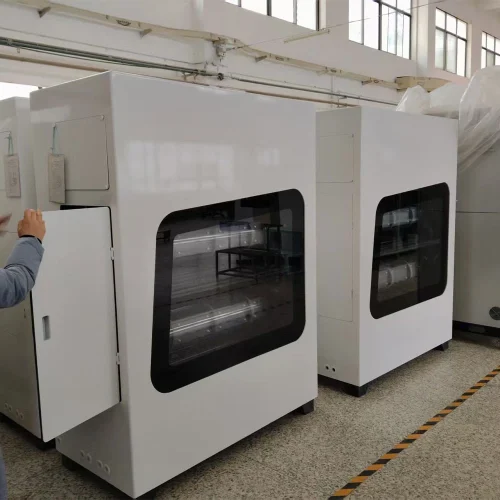

Sodium hypochlorite generator parameter

| Product name | SHC-5000G |

|---|---|

| Effective chlorine yield | 5000g/H |

| Concentration | 6-10g/L(6000-10000ppm) |

| Power | 60KW |

| Salt consumption | 3.2KG/KG |

| Size | 2300*900*2000 |

| Voltage | 380/50 |

Advantages of Sodium Hypochlorite Generators

Cost – Effectiveness

Cost – effectiveness is a significant factor when choosing a water treatment solution, and our Sodium Hypochlorite Generator shines in this aspect. Firstly, as mentioned earlier, the in – situ generation method reduces the need for purchasing and transporting pre – made chemicals. This alone can result in substantial cost savings. Secondly, the generator’s energy – efficient design helps keep operating costs low. It consumes minimal electricity while producing a high volume of effective sodium hypochlorite solution. Thirdly, its long – lasting construction means fewer replacement and maintenance costs over time. All in all, investing in our Sodium Hypochlorite Generator is a smart financial decision that pays off in the long term.

Environmentally Friendly

In today’s world, environmental friendliness is a top priority, and our Sodium Hypochlorite Generator is design with the environment in mind. By producing sodium hypochlorite on – site, it reduces the carbon footprint associated with the transportation of pre – made chemicals. Additionally, the generator uses a natural and renewable resource – salt – as its main raw material. This is a sustainable alternative to traditional water treatment chemicals that may have a negative impact on the environment. Moreover, the by – products of the electrolysis process, such as hydrogen gas, can be safely vented or, in some cases, even used for other purposes, further minimizing waste.

Customer Support

Field reinjection application

Equipment Maintenance

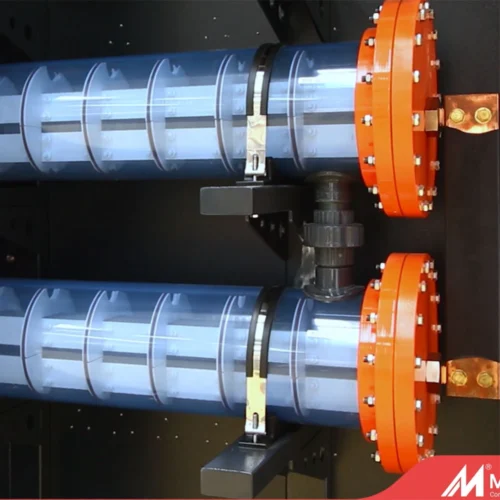

Regular inspection of the electrolytic cell is crucial. The electrolytic cell is the core component of the sodium hypochlorite generator. Because scale and impurities will be generate during the electrolysis process, long – term operation may lead to electrode corrosion. Therefore, it is necessary to regularly clean the electrolytic cell and replace damaged electrodes to ensure the normal operation of the equipment. Generally, it is recommended to inspect and maintain the electrolytic cell once a month or once a quarter.

Dosing Control

Accurate control of the sodium hypochlorite dosage is very important. Insufficient dosage will lead to incomplete disinfection and excessive microorganisms in water; excessive dosage will result in the problem of high residual chlorine, which will affect the taste of water quality and may generate harmful disinfection by – products. Waterworks usually determine the appropriate dosage according to different water qualities, such as the pollution degree of raw water, water temperature and other factors, through experiments and online monitoring equipment. Generally, the dosage is controlled between 0.3 – 4mg/L.

Water Quality Monitoring

While using sodium hypochlorite for disinfection, it is necessary to strengthen water quality monitoring. In addition to monitoring microbiological indicators, it is also necessary to pay attention to the generation of disinfection by – products. For example, sodium hypochlorite disinfection may produce disinfection by – products such as trihalomethanes. And advanced detection technologies such as gas chromatography are need for monitoring to ensure the safety of drinking water. At the same time, it is also necessary to monitor parameters such as the pH value of water, because the pH value will affect the disinfection effect of sodium hypochlorite, and the appropriate pH value range is generally between 6.5 – 8.5.

our Sodium Hypochlorite Generator, with its 0.6 – 0.8% concentration range, is the perfect solution for all your water treatment needs. It offers a combination of high performance, versatility, cost – effectiveness, and environmental friendliness. Don’t miss out on the opportunity to improve the quality of your water treatment process. Contact us today to learn more about our product and how it can benefit you.

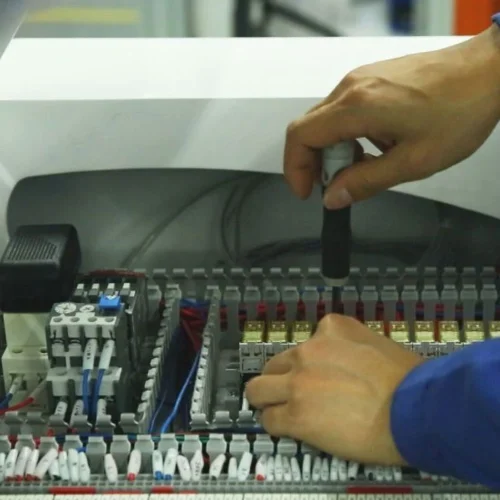

Factory advantage

We have R&D centers, production centers, data centers and marketing centers. It is commit to providing technical support and innovative applications for improving public health security. Since its establishment, the company has obtained 12 invention patents and environmental management system certification. The company also has more than 30 test reports, covering surface and other different concentration detection projects. The series products sell well all over the country, and exported to such as Thailand, Malaysia, Cambodia, Brazil, South Africa, South America and other more than 20 countries and regions. The company has a perfect product sales and service system, to meet the needs of different customers with more professional services, so that to provide the best products and services for public health!

Our sodium hypochlorite generators are easy to operate and maintain. They come with user-friendly interfaces and require minimal training. Additionally, they are energy-efficient, reducing your operating costs and environmental footprint.

Don’t settle for outdated disinfection methods. Upgrade to our advanced sodium hypochlorite generators and take your operations to the next level. At the same time, contact us today to learn more!

Customer feedback