Introduction

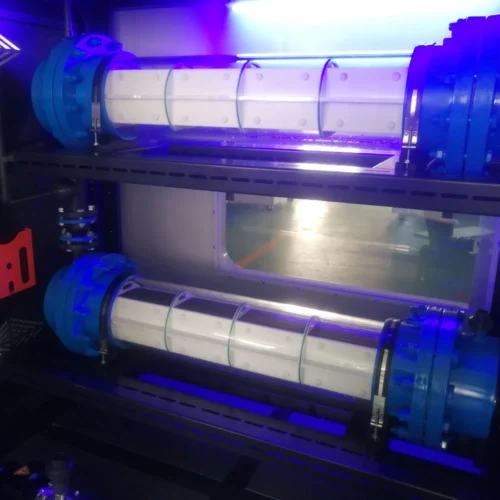

The SHT-5000G Sodium Hypochlorite Generator is a cutting-edge water treatment device designed to deliver efficient, safe, and also cost-effective disinfection. Engineered for large-scale applications, this system produces high-concentration sodium hypochlorite solution on-site, eliminating the risks and also costs associated with transporting and storing hazardous chemicals. Whether for municipal water treatment, industrial wastewater management, or swimming pool sanitation, the SHT-5000G ensures reliable performance and compliance with strict environmental standards.

Sodium hypochlorite generator parameter

| Product name | SHC-5000G |

|---|---|

| Effective chlorine yield | 5000g/H |

| Concentration | 6-10g/L(6000-10000ppm) |

| Power | 30KW |

| Salt consumption | 3.2KG/KG |

| Size | 1600*800*2000mm |

| Voltage | 380V/50hz |

Core Advantages

1. On-Site Production for Ultimate Safety

The SHT-5000G generates sodium hypochlorite directly from salt and water, eliminating the need for bulk chemical storage. This reduces risks of spills, leaks, and transportation accidents. Moreover, the system produces fresh disinfectant on demand, ensuring optimal efficacy compared to pre-made solutions that degrade over time.

2. High Efficiency and Low Operational Costs

Featuring advanced electrolysis technology, the SHT-5000G achieves 99.99% bacterial reduction within minutes. Its energy-efficient design consumes 4.3–4.5 kWh per kilogram of sodium hypochlorite, significantly lower than traditional chlorination methods. Additionally, the system uses common table salt as the primary raw material, minimizing long-term operational expenses.

3. Modular Design for Flexibility

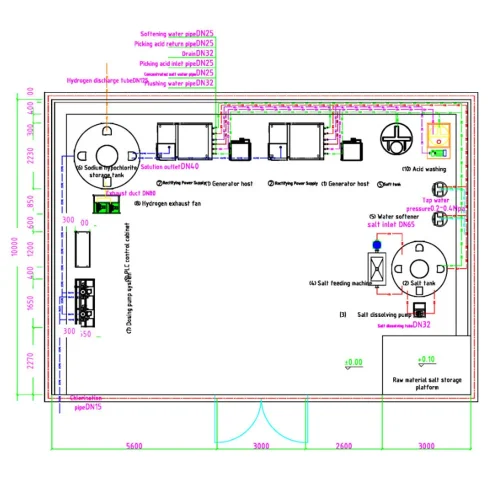

The SHT-5000G is built with a compact, skid-mounted structure, allowing easy installation in limited spaces. Meanwhile, its modular architecture enables seamless scalability—multiple units can be integrated to meet increasing demand. For example, a wastewater treatment plant expanding its capacity can add more modules without replacing the entire system.

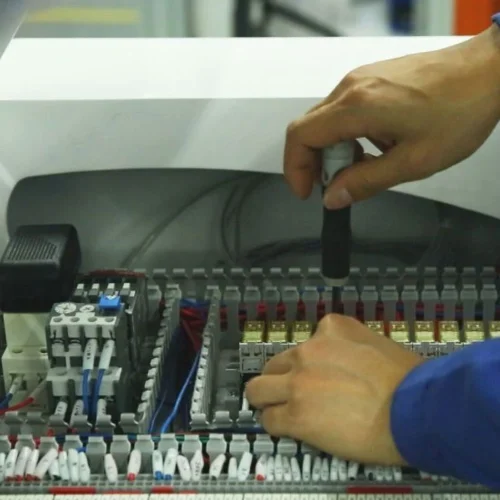

4. Intelligent Control for Hassle-Free Operation

Equipped with a PLC-based control system, the SHT-5000G automates salt dissolution, electrolysis, and dosing processes. Real-time monitoring of parameters like voltage, current, and solution concentration ensures consistent output. Operators can adjust settings remotely via a user-friendly interface, reducing manual intervention and errors at the same time.

5. Environmentally Friendly Operation

By using salt and also electricity, the SHT-5000G avoids harmful byproducts like chloramines or trihalomethanes (THMs) generated by chlorine gas systems. The only byproduct is hydrogen gas, which is safely vented. This aligns with global sustainability goals and reduces the carbon footprint of water treatment facilities.

Technical Specifications

Applications

The SHT-5000G ensures safe drinking water by neutralizing pathogens like E. coli and Legionella. Therefore, its high output makes it ideal for large water treatment plants serving urban populations.

2. Industrial Wastewater Disinfection

For industries such as food processing, pharmaceuticals, and textiles, the system eliminates harmful bacteria and organic contaminants, ensuring wastewater meets discharge standards.

3. Swimming Pool Sanitation

By continuously dosing sodium hypochlorite, the SHT-5000G maintains crystal-clear pool water while minimizing skin and eye irritation caused by traditional chlorine tablets.

4. Agricultural and Aquacultural Use

The system disinfects irrigation water to prevent crop diseases and treats aquaculture ponds to control algae and pathogens, enhancing fish and shrimp at the same time.

How It Works

Salt Dissolution: High-purity salt is mixed with water in a brine tank to create a 3–4% saline solution.

Electrolysis: The saline solution flows into the electrolytic cell, where direct current (12V) splits sodium chloride into chlorine gas and sodium hydroxide.

Reaction: Chlorine gas reacts with sodium hydroxide to form sodium hypochlorite (NaClO), the active disinfectant.

Dosing: The generated solution is pumped directly into the water stream, ensuring immediate disinfection.

FAQ

1. What safety measures does the SHT-5000G include?

The system features overcurrent protection, temperature sensors, and hydrogen gas detectors. It also complies with international safety standards like CE and ISO.

2. Can the SHT-5000G handle varying water qualities?

Yes. The PLC system automatically adjusts electrolysis parameters based on water salinity and pH, ensuring consistent performance even with brackish or hard water.

3. Is professional training required for operation?

While the system is user-friendly, operator training is recommended to optimize settings and troubleshoot minor issues.

Factory advantage

We have R&D centers, production centers, data centers and marketing centers. It is committe to providing technical support and innovative applications for improving public health security. Since its establishment, the company has obtained 12 invention patents and environmental management system certification. The company also has more than 30 test reports, covering surface and other different concentration detection projects. The series products sell well all over the country, and exported to such as Thailand, Malaysia, Cambodia, Brazil, South Africa, South America and other more than 20 countries and regions. The company has a perfect product sales and service system. To meet the needs of different customers with more professional services. So that to provide the best products and services for public health!

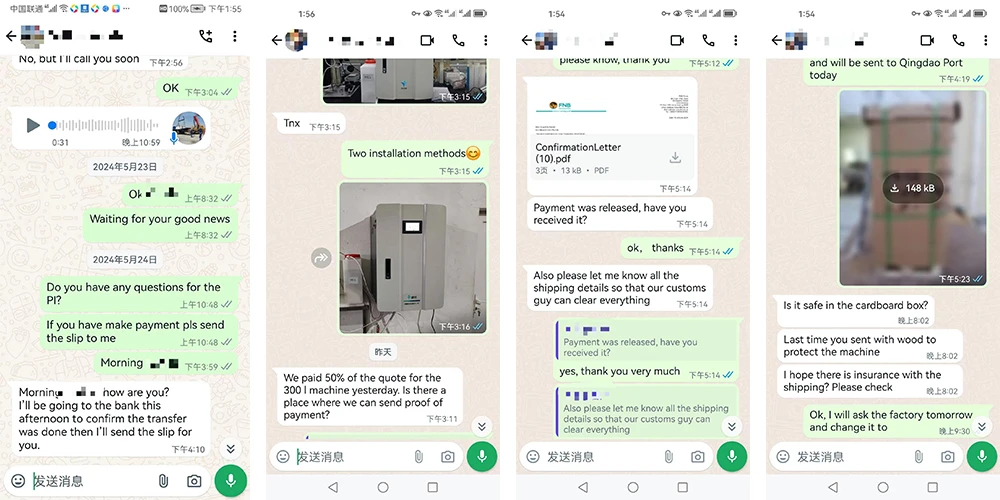

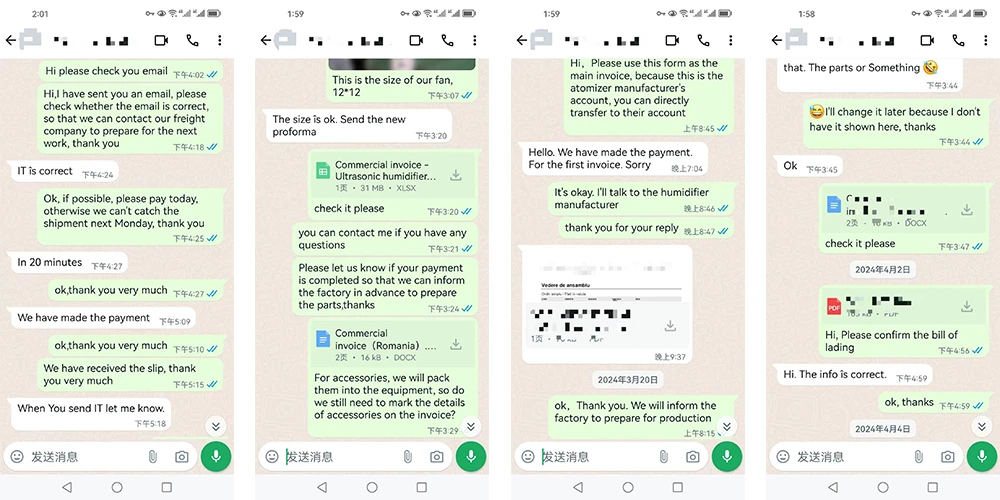

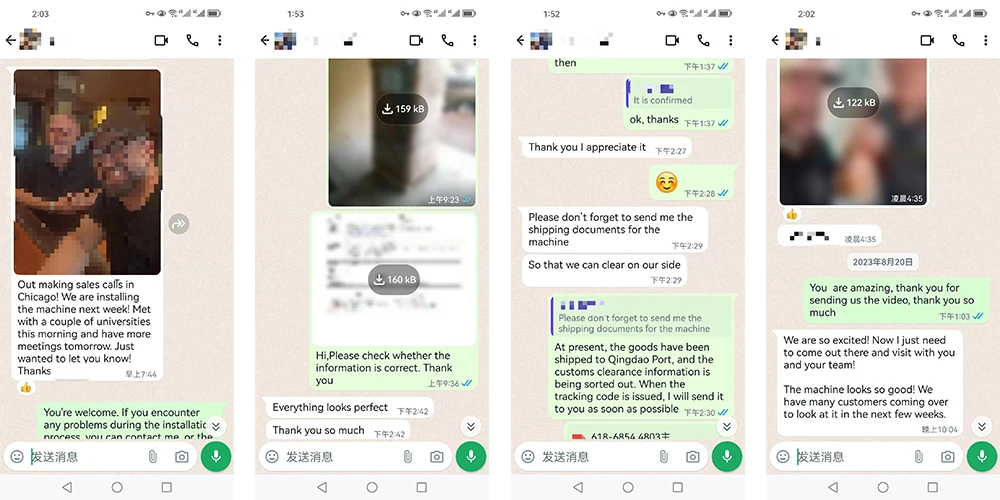

Customer feedback