Lorem ipsum dolor sit amet...

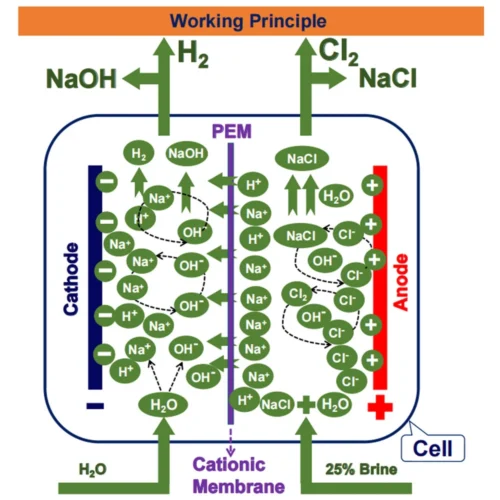

The Sodium Hypochlorite Generator for Water Plants-10KG produces sodium hypochlorite solution through the electrolysis of brine.

The chemical equation is: NaCl+H2O→(electrolysis)NaClO+H2↑

During this process, the sodium chloride (NaCl) solution is electrolyzed in the electrolytic cell. Chloride ions (Cl–) lose electrons at the anode to generate chlorine gas (Cl2), and the chlorine gas then reacts with water to form hypochlorous acid (HClO) and hydrochloric acid (HCl). Hypochlorous acid is the main disinfecting component and has strong oxidizing properties.

Hypochlorous acid can destroy the cell walls and cell membranes of bacteria and viruses, causing protein denaturation and thus achieving the purpose of sterilization and disinfection. It can effectively kill pathogenic microorganisms such as Escherichia coli, Salmonella, and Vibrio cholerae in water and can also remove microorganisms such as algae in water.

Sodium hypochlorite generator parameter

| Product name | SHC-10000G |

|---|---|

| Effective chlorine yield | 10000g/H |

| Concentration | 6-10g/L(6000-10000ppm) |

| Power | 60KW |

| Salt consumption | 3.2KG/KG |

| Size | 2300*900*2000 |

| Voltage | 380/50 |

Advantages of Sodium Hypochlorite Generators

High Safety

Compared with chlorine gas, the sodium hypochlorite generator prepares sodium hypochlorite solution on – site. Avoiding the safety risks during the storage and transportation of chlorine gas. Chlorine gas is a highly toxic gas, and once leaked, it will cause serious harm to human bodies and the environment. The sodium hypochlorite solution is relatively stable, and under normal use and storage conditions, it has higher safety.

Good Disinfection Effect

Sodium hypochlorite can quickly release hypochlorous acid in water, and its disinfection effect is equivalent to that of chlorine gas. With an appropriate dosage, the microbiological indicators of the treated water can meet the national drinking water health standards. For example, it performs well in killing microorganisms such as bacteria, viruses. And protozoa in water and can effectively prevent water – borne infectious diseases.

Simple Operation

The sodium hypochlorite generator has a high degree of automation. Operators can master its operation method through simple training and can easily adjust the output and dosage of sodium hypochlorite according to the changes in water quality and quantity. For example, through the control system, parameters such as electrolytic current and electrolysis time can be set to achieve automated production and dosing.

Reasonable Cost

Its main raw material is table salt, which has a wide range of sources and relatively stable prices. Although the initial investment of the equipment may be high, from the perspective of long – term operation cost, in some large – scale waterworks, through reasonable management and operation, the disinfection cost can be effectively controlle. Moreover, with the development of technology, the energy consumption of the sodium hypochlorite generator is also gradually decreasing.

Field reinjection application

Equipment Maintenance

Regular inspection of the electrolytic cell is crucial. The electrolytic cell is the core component of the sodium hypochlorite generator. Because scale and impurities will be generated during the electrolysis process, long – term operation may lead to electrode corrosion. Therefore, it is necessary to regularly clean the electrolytic cell and replace damaged electrodes to ensure the normal operation of the equipment. Generally, it is recommended to inspect and maintain the electrolytic cell once a month or once a quarter.

Dosing Control

Accurate control of the sodium hypochlorite dosage is very important. Insufficient dosage will lead to incomplete disinfection and excessive microorganisms in water; excessive dosage will result in the problem of high residual chlorine, which will affect the taste of water quality and may generate harmful disinfection by – products. Waterworks usually determine the appropriate dosage according to different water qualities, such as the pollution degree of raw water, water temperature and other factors, through experiments and online monitoring equipment. Generally, the dosage is controlled between 0.3 – 4mg/L.

Water Quality Monitoring

While using sodium hypochlorite for disinfection, it is necessary to strengthen water quality monitoring. In addition to monitoring microbiological indicators, it is also necessary to pay attention to the generation of disinfection by – products. For example, sodium hypochlorite disinfection may produce disinfection by – products such as trihalomethanes. And advanced detection technologies such as gas chromatography are need for monitoring to ensure the safety of drinking water. At the same time, it is also necessary to monitor parameters such as the pH value of water, because the pH value will affect the disinfection effect of sodium hypochlorite, and the appropriate pH value range is generally between 6.5 – 8.5.

Factory advantage

We have R&D centers, production centers, data centers and marketing centers. It is commit to providing technical support and innovative applications for improving public health security. Since its establishment, the company has obtained 12 invention patents and environmental management system certification. The company also has more than 30 test reports, covering surface and other different concentration detection projects. The series products sell well all over the country, and exported to such as Thailand, Malaysia, Cambodia, Brazil, South Africa, South America and other more than 20 countries and regions. The company has a perfect product sales and service system, to meet the needs of different customers with more professional services, so that to provide the best products and services for public health!

Our sodium hypochlorite generators are easy to operate and maintain. They come with user-friendly interfaces and require minimal training. Additionally, they are energy-efficient, reducing your operating costs and environmental footprint.

Don’t settle for outdated disinfection methods. Upgrade to our advanced sodium hypochlorite generators and take your operations to the next level. At the same time, contact us today to learn more!

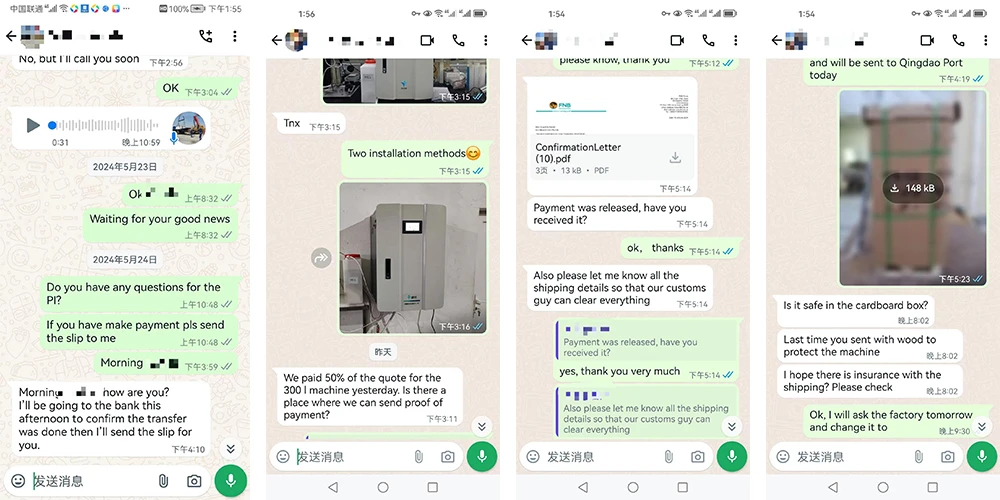

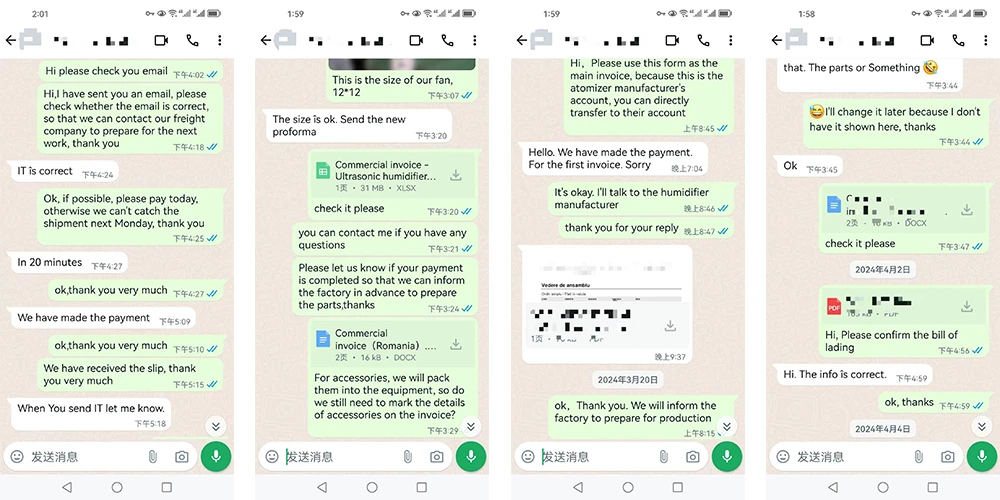

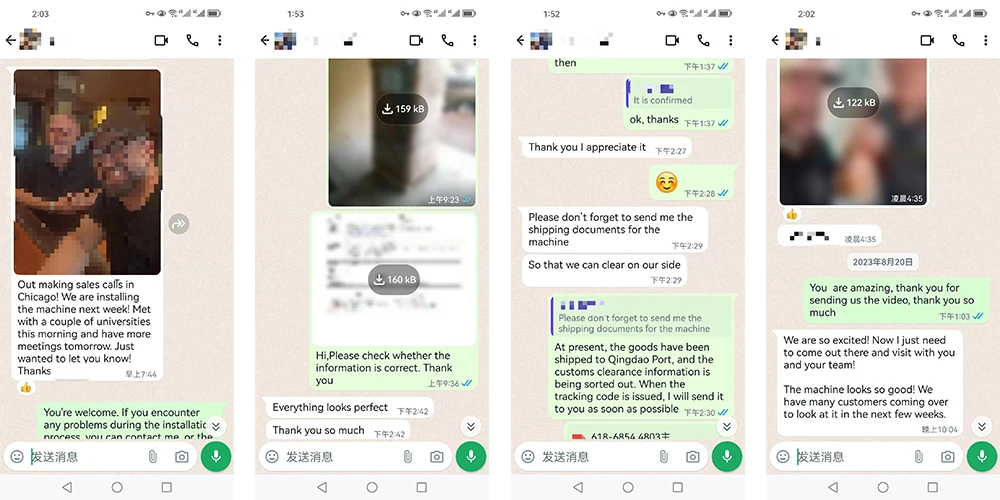

Customer feedback