Understanding Sodium Hypochlorite Generators

The generated sodium hypochlorite can be used in various stages of water treatment. For example, it can be added to raw water to kill pathogens and make the water safe for consumption. It can also be used in wastewater treatment to reduce the levels of contaminants and improve the quality of the discharged water.

Sodium hypochlorite generators offer several advantages over other disinfection methods. One of the main advantages is cost-effectiveness. Since these generators produce sodium hypochlorite on-site, there is no need to purchase and transport large quantities of pre-made bleach. This can result in significant savings in terms of both cost and logistics.

Another advantage is safety. Sodium hypochlorite generators produce a relatively stable solution that is less likely to cause accidental spills or releases compared to concentrated bleach. Additionally, the generated solution can be adjuste to the desired concentration, reducing the risk of over-dosing or under-dosing.

In conclusion, sodium hypochlorite generators are an important tool in water treatment. They offer a cost-effective and safe way to produce a powerful disinfectant that can help ensure the quality and safety of our water supply.

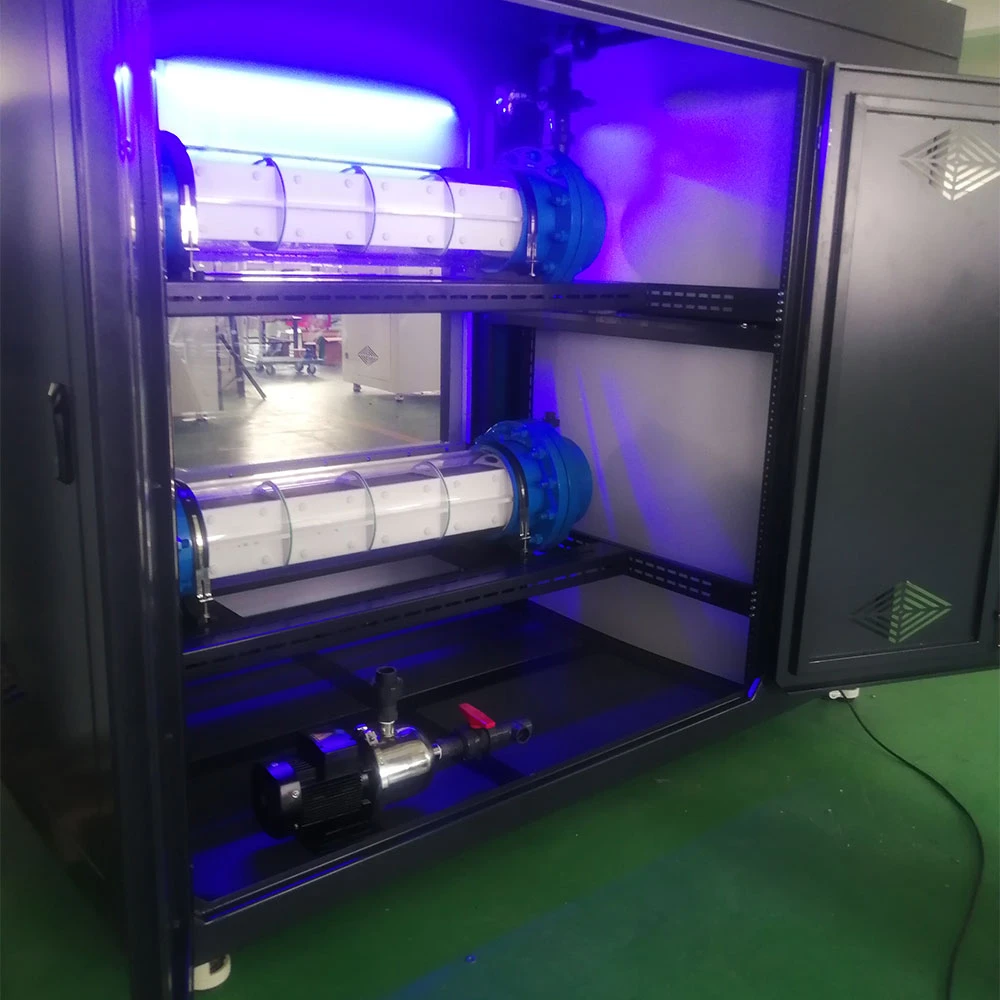

Sodium hypochlorite generator parameter

| Product name | SHC-1200G |

|---|---|

| Effective chlorine yield | 1200g/H |

| Concentration | 6-10g/L(6000-10000ppm) |

| Power | 7KW |

| Salt consumption | 3.2KG/KG |

| Size | 2300*900*2000 |

| Voltage | 380/50 |

Performance characteristics of sodium hypochlorite generator

(一)Efficient Disinfection

Sodium hypochlorite generators offer highly efficient disinfection for water in waterworks. The generated sodium hypochlorite is a powerful disinfectant that can effectively kill a wide range of bacteria, viruses, and other harmful microorganisms. For example, studies have shown that it can eliminate common waterborne pathogens such as E. coli and Salmonella. The electrolysis process ensures a continuous supply of fresh disinfectant, which can be adjust to the optimal concentration for different water sources and treatment requirements. This means that waterworks can rely on these generators to maintain a high level of water quality and safety.

(二)Cost-Effective Solution

Compared to other treatment methods, sodium hypochlorite generators are a cost-effective solution. As mentioned earlier, these generators produce sodium hypochlorite on-site, eliminating the need to purchase and transport large quantities of pre-made bleach. This can result in significant savings in terms of both cost and logistics. Additionally, the generators are energy-efficient and require minimal maintenance, further reducing operational costs. For example, a waterworks that switches to sodium hypochlorite generators can expect to save thousands of dollars per year in chemical costs alone.

(三)Environmentally Friendly

Sodium hypochlorite generators are also an environmentally friendly option for water treatment. Unlike some other disinfection methods, they do not produce harmful by-products or release toxic chemicals into the environment. The generated sodium hypochlorite is biodegradable and breaks down into harmless substances over time. Moreover, these generators can help reduce the use of chemical pesticides and fertilizers, which can have a negative impact on the environment. For instance, by using sodium hypochlorite generators in water treatment, waterworks can contribute to a more sustainable future by reducing their carbon footprint and protecting the environment.

How They Work

Sodium hypochlorite generators in waterworks operate through a specific process. Firstly, a saltwater solution is introduce into the generator. This solution typically contains a certain concentration of sodium chloride. Then, an electric current is passed through the solution. This electrolysis process causes a chemical reaction to take place. At the anode, chloride ions are oxidized to form chlorine gas. Simultaneously, at the cathode, water is reduce to form hydroxide ions and hydrogen gas. The chlorine gas reacts with the hydroxide ions to form sodium hypochlorite.

The generated sodium hypochlorite solution can then be use for water treatment. The concentration of the solution can be adjuste by controlling the amount of salt in the input solution and the intensity of the electric current. For instance, if a higher concentration of sodium hypochlorite is need for more effective disinfection, more salt can be add or the current can be increase.

This working mechanism ensures a continuous supply of fresh sodium hypochlorite for water treatment. It is a reliable and efficient method that can be easily integrate into the operations of waterworks. Moreover, the process is relatively simple and can be monitor and controll to meet the specific needs of different water treatment applications.

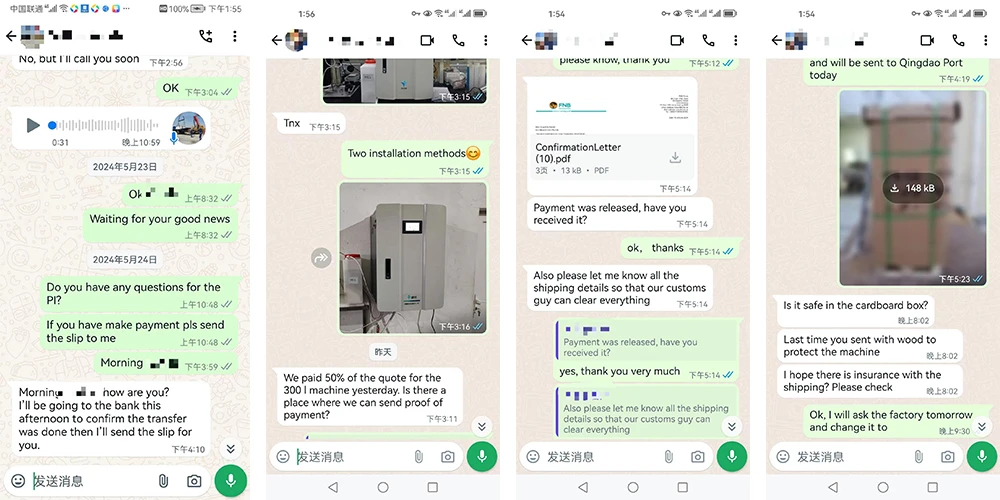

Field reinjection application

Factory advantage

We have R&D centers, production centers, data centers and marketing centers. It is committe to providing technical support and innovative applications for improving public health security. Since its establishment, the company has obtained 12 invention patents and environmental management system certification. The company also has more than 30 test reports, covering surface and other different concentration detection projects. The series products sell well all over the country, and exported to such as Thailand, Malaysia, Cambodia, Brazil, South Africa, South America and other more than 20 countries and regions. The company has a perfect product sales and service system. To meet the needs of different customers with more professional services. So that to provide the best products and services for public health!

Customer feedback