Electrolysis principle of weak alkali water equipment

The purified tap water is passed through the electrolytic cell with direct current

(according to the principle of same repulsion and opposite attraction),

and the positive cations such as calcium, potassium and magnesium in the water will be

collecte into the cathode to become alkaline electrolytic reducing water with (-) potential,

while the negative potential chlorine, trichloromethane, phosphoric acid and sulfuric acid

will become alkaline electrolytic reducing water with negative potential. Anions such as

nitric acid converge to the anode to form acidic oxidized water with a (+) potential.

During electrolytic ion exchange, due to the action of electric field, cations such as

free calcium, magnesium, potassium and sodium in the water move to the negative side,

so that the content of trace elements in the alkaline water on the negative side of the human body

is increase intentionally, and these beneficial elements are in the form of ions, which is more suitable for

human absorption

Weakly alkaline ionized water equipment parameters

| Model | Weakly alkaline ionized water equipment |

|---|---|

| Inlet water pressure | 0.05~0.35MPa |

| Power supply | 380V 50Hz(three-phase five-wire system) |

| Inlet water temperature | 10~35℃ |

| Water discharge | 1000L/H |

| Production method: | continuous electrolysis |

| Effluent PH value | alkaline water 7.4-10.0 |

| Effluent ratio | alkaline water effluent rate is as high as 70%-90% |

| weight | 130kg |

| Size | 70*60*175cm |

Weak alkali water equipment advantage

1, the equipment uses titanium coated platinum-iridium electrode material to prevent the oxidation of the plate during the electrolytic process, improve the life of the electrode and the entire equipment.

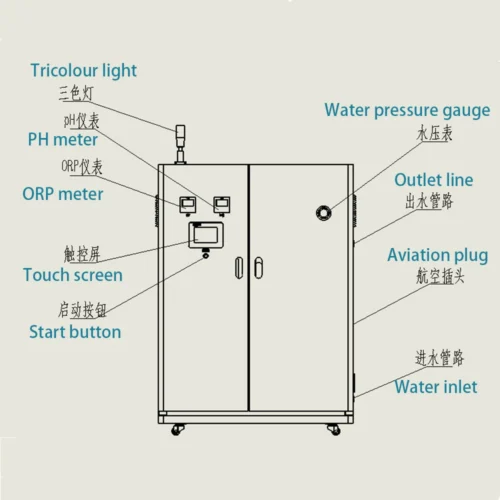

2, the equipment set water, electrical control in one, easy to use, small footprint.

3, the device online display pH value, conductivity value, electrolysis, current and other parameters.

4, the equipment electrolytic process, can effectively kill bacteria, viruses and other harmful substances, so that drinking water more safe, clean, sanitary.

6, in the process of water production, you can produce water with different PH values (7.0-10.0) by adjusting the current to meet the needs of different customers.

7, the equipment has positive and negative reverse pole cleaning function, the equipment can be cleane in time, extend the service life of the electrolytic cell.

8, the use of electrolytic water manufacturing process: electric separation combination technology to ensure the treatment of water quality. The system is fully formulated and full of allowance, fully automatic operation, stable effluent water quality,

Our factory

Our qualifications

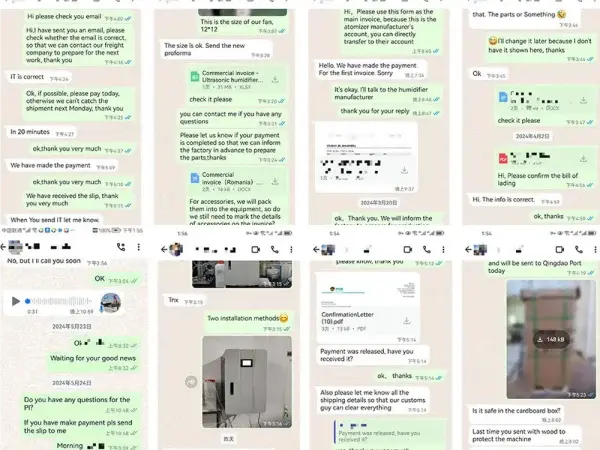

Customer feedback